Injection moulding is a key process for the production of most technical components used in the construction, electrical, furniture, household appliance and toy industries, such as computer components and keyboards, mobile phone housings and household appliance parts. These industries in particular demand the highest quality, process stability and reproducibility.

For more than 40 years the Piovan Group has been manufacturing industrial automation systems for the technical moulding of high quality plastic articles. It designs complex turnkey systems where the numerous materials and high standards require ever greater process flexibility.

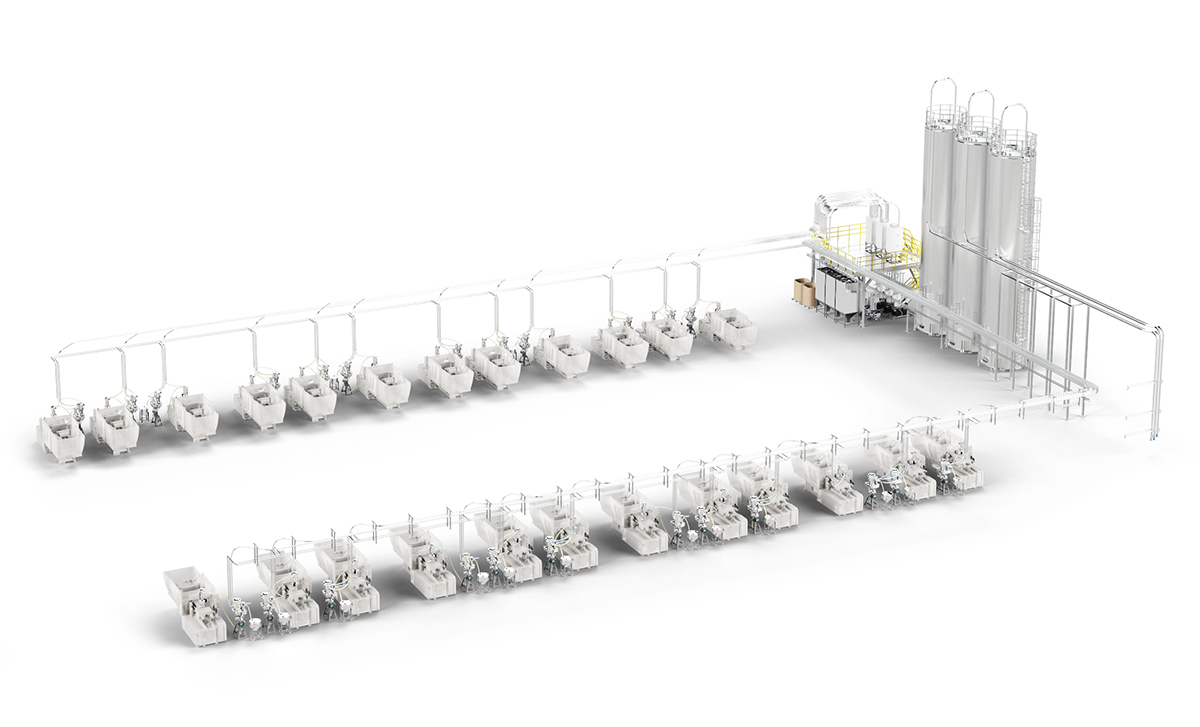

Management of material batches, centralised transport with automatic sorting units, self-adaptive dehumidification based on actual hourly production, accurate dosing even at low quantities and efficient and precise mould temperature control guarantee the maximum quality of the finished product.

Piovan also provides software for process management and quality traceability of production batches that easily integrates with the ERP used.

Quantum are gravimetric blenders suitable for all plastic materials, immune to vibrations and easy to use. All the surfaces that come into contact with the process material are stainless steel and can be used in the most critical environments, like the medical and food packaging sectors. Its semispherical shape assures perfect mixing without stagnation. The range can have up to 6 dosing stations, which can be easily removed, for emptying or cleaning. The mixer, which can be installed remotely over the processing machine, assures the best mixing, especially after conveying of materials with different densities over long distances.

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.