Automation systems for fibre and strapping production

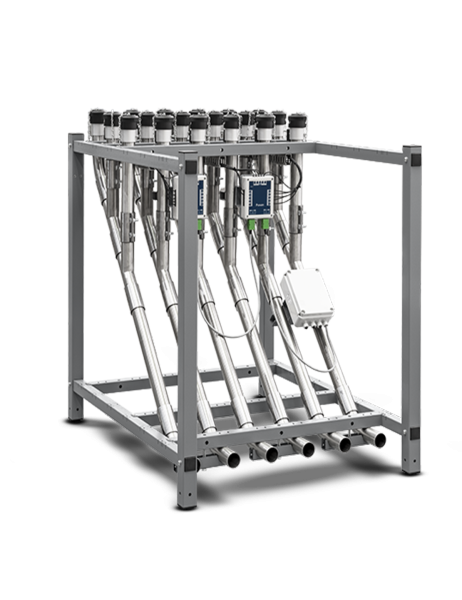

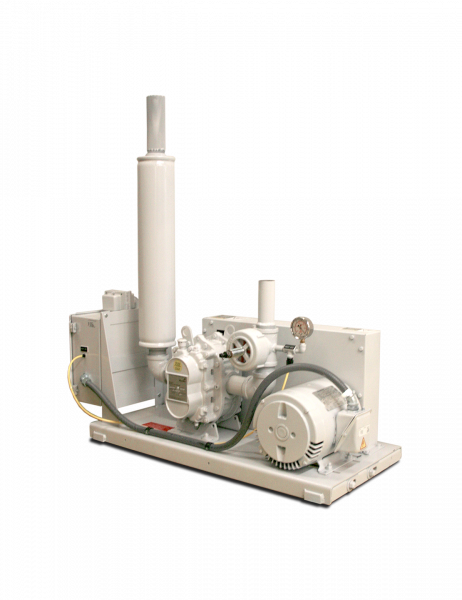

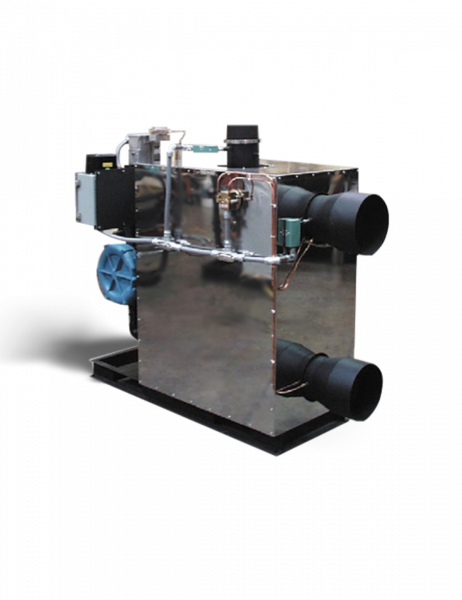

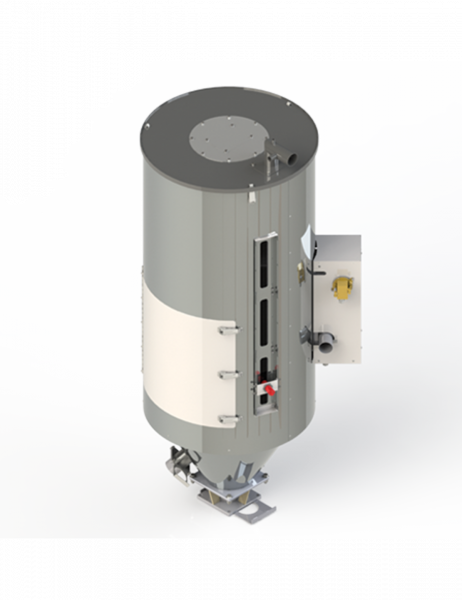

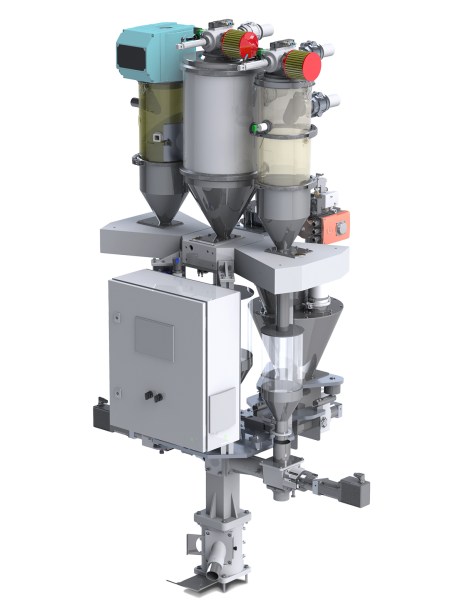

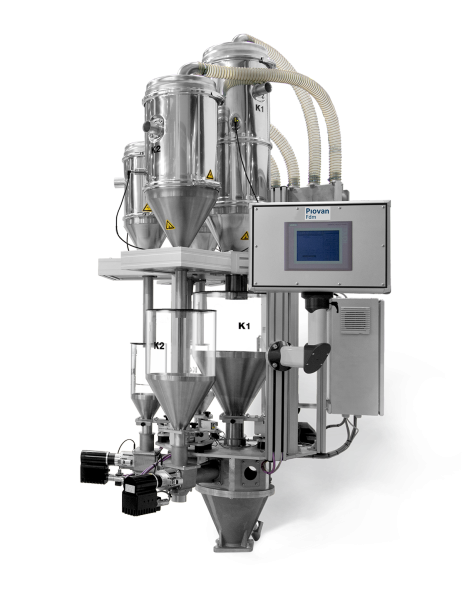

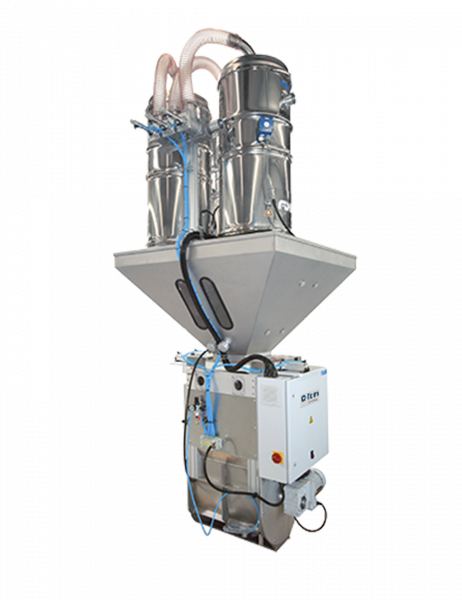

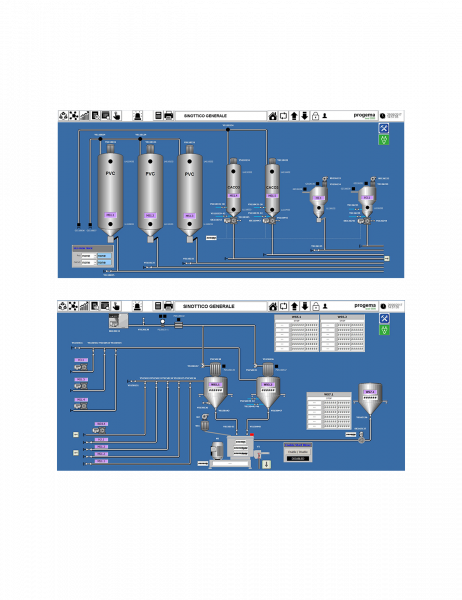

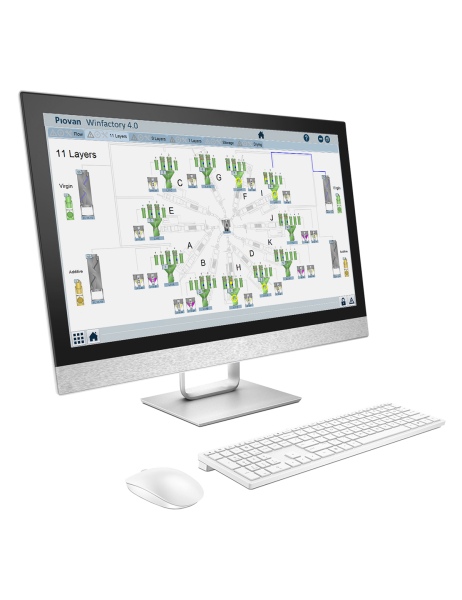

The initial stages of spinning process are always the most important to outline the characteristics of the fibres and become essential when the goal is to achieve superior high-quality performances. Behind common products like filament yarns, fabrics, carpets, geotextiles or strapping bands for packaging, there are advanced technologies for feeding, crystallising, drying and dosing of polymers that Piovan has developed over the years and successfully installed for many customers around the world.

Cutting edge technology to optimize the fibre and strapping extrusion process

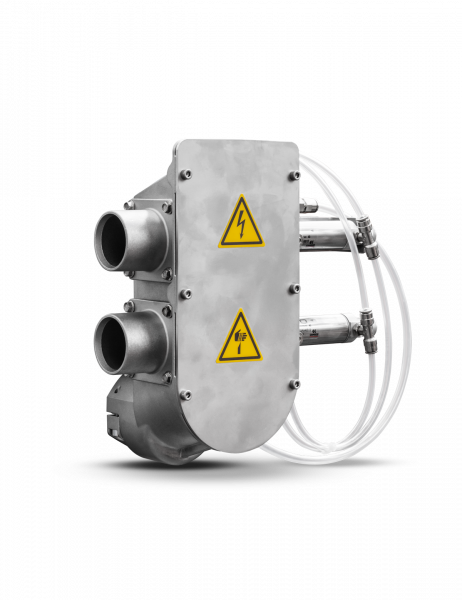

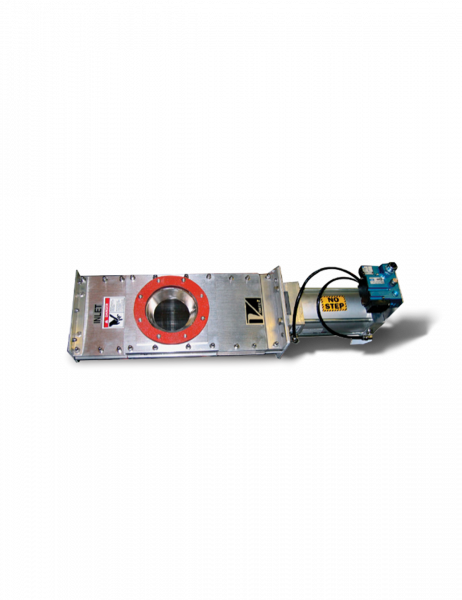

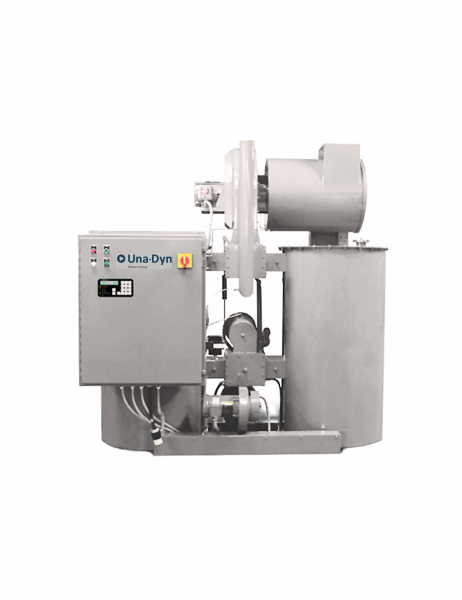

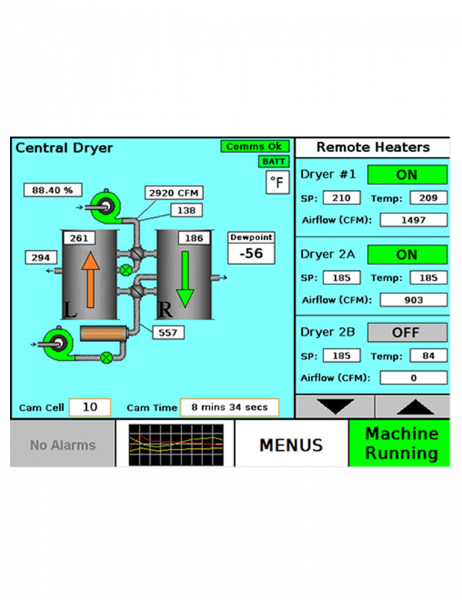

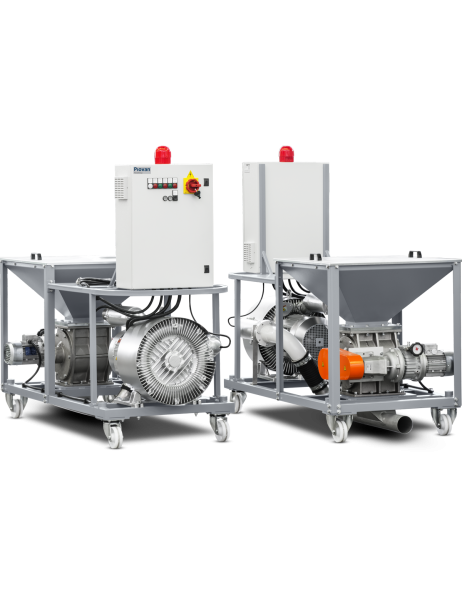

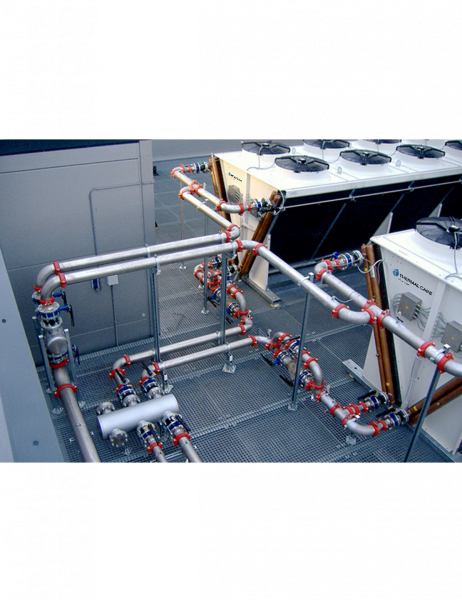

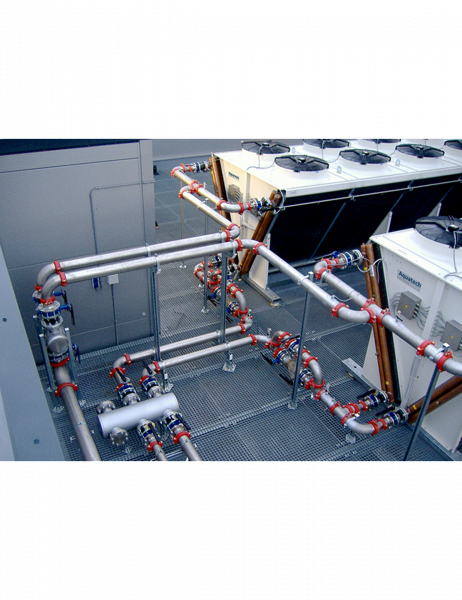

Polyester, Polypropylene and Polyamide are processed in the Piovan systems with the utmost care to guarantee a stable extrusion process and reliable production over 24 hours. Piovan equipment is specifically designed for the industrial environment, as required by fibres and strappings factories.

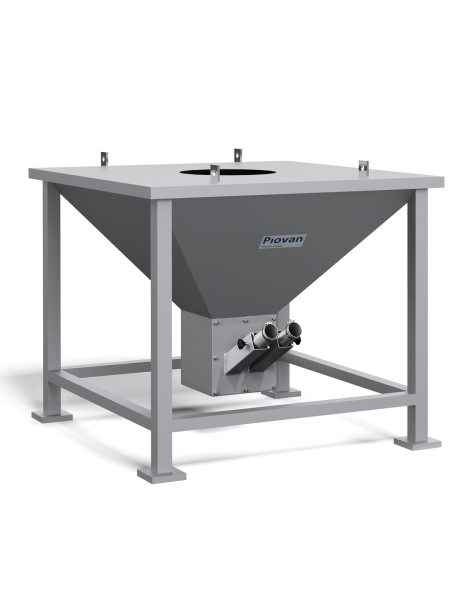

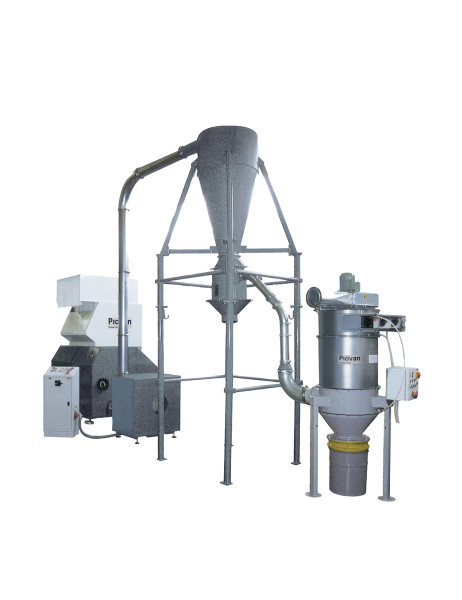

In addition to processing virgin polymers, the PiovanGroup designs complete technologies for processing PET flakes from post-consumer bottles suitable for the production of staple fibres or PET strapping bands, such as storage silos, bulk handling systems, pneumatic conveying systems, dedusters, crystallisers, dryers and gravimetric blenders. The machine and engineering portfolio also includes sustainable solutions that guarantee optimum process stability and energy efficiency.

Thanks to the synergy among the various companies of the Group, to the wide technological portfolio available and to the long-term collaboration with the main OEMs of the sector, Piovan is able to offer its Customers experience, competence and reliability to design the most suitable plant for the production needs.