Piovan

The parent company Piovan S.p.A. is a global leader in the development and production of automation systems for storage, conveying and processing of plastic and food.

Headquartered in Santa Maria di Sala, Venice, the Group was born from Piovan, founded in 1934 as a mechanical engineering company. In 1964 it entered the plastics industry and specialises in the manufacturing of auxiliary equipment.

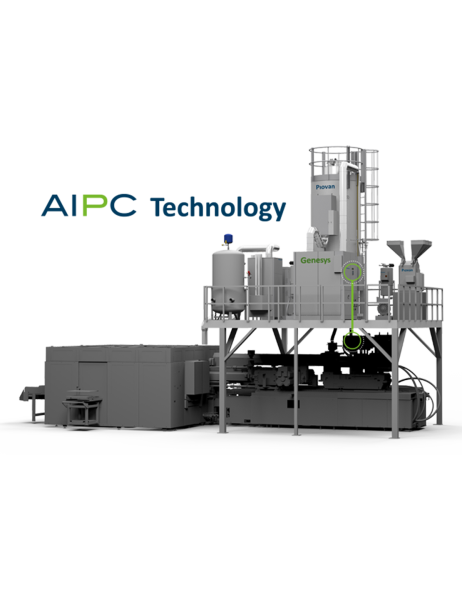

As a company of the Group, Piovan S.p.A. has always been on the cutting edge of research for integrated eco-sustainable, high-efficiency solutions that optimise the use of raw materials and energy resources, allowing for intelligent transformation of polymers, sustaining the evolution of material recycling techniques.

Piovan S.p.A. operates in many sectors like PET preforms & bottles, rigid packaging, automotive components, technical parts, medical solutions, thermoforming & technical sheets, flexible film, pipes, profiles, cables, fibres & strapping, recycling and compounds.

In October 2018, Piovan S.p.A. enters the Italian Stock Exchange.

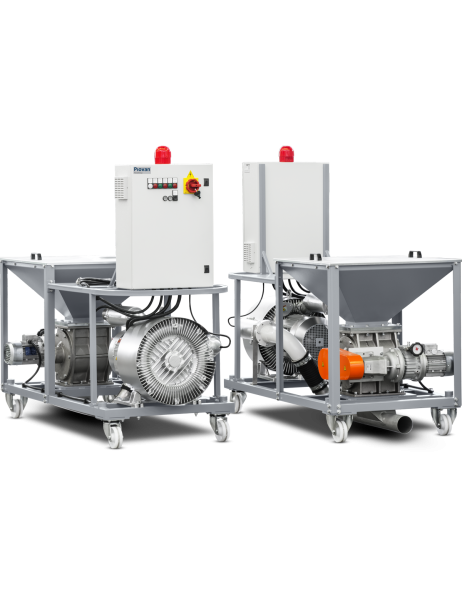

Feeding & Conveying

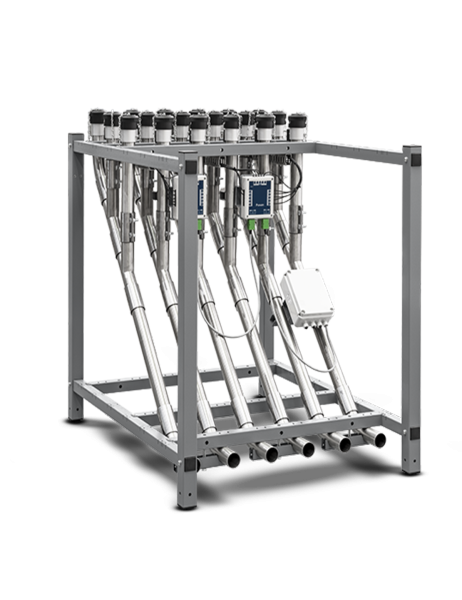

The range of Piovan solutions spans from stand-alone single material loaders to central multiple material systems.

Drying & Dehumidifying

Broad selection of technologies to perform the drying process in the best condition possible for the raw material.

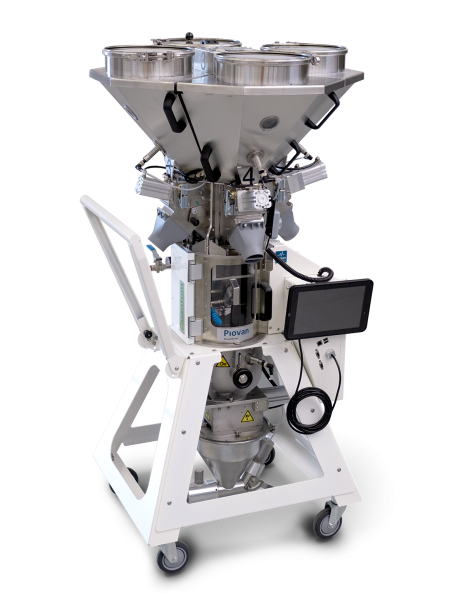

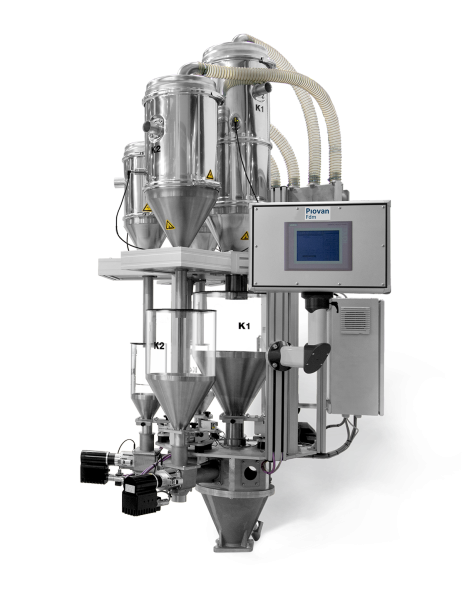

Dosing & Blending

Volumetric, gravimetric, loss-in-weight, continuous or batch, are the technologies implemented in the series of blenders and dosing units of Piovan.

Temperature control

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

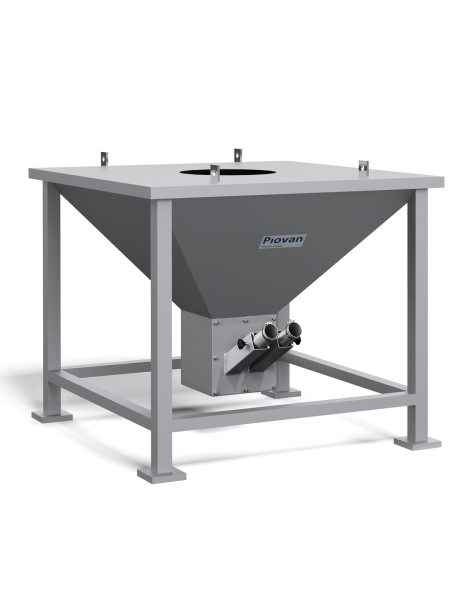

Storage

Wide range of solutions that includes from the small movable storage silos on wheels, up to the external silos to stock tonnes of material. The solutions can be totally tailor made on customer request.

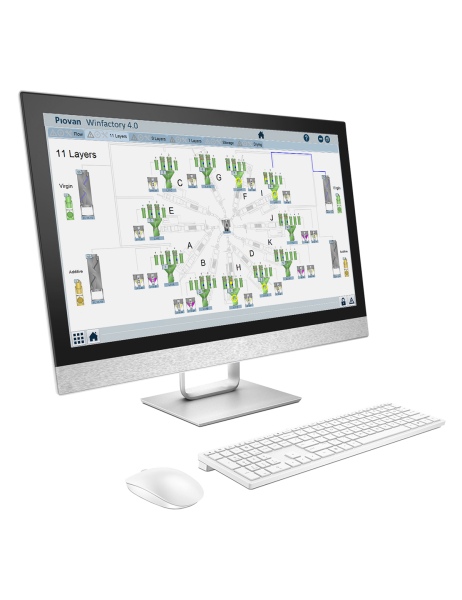

Software & Control systems

Process integration and control systems are key to maximizing efficiency and achieving high performance.

Lab-tech

The simplest way of measuring AA levels in PET preforms. The Piovan Lab-Tech range allows utmost production monitoring, by providing real time analysis of acetaldehyde content in the PET preforms.

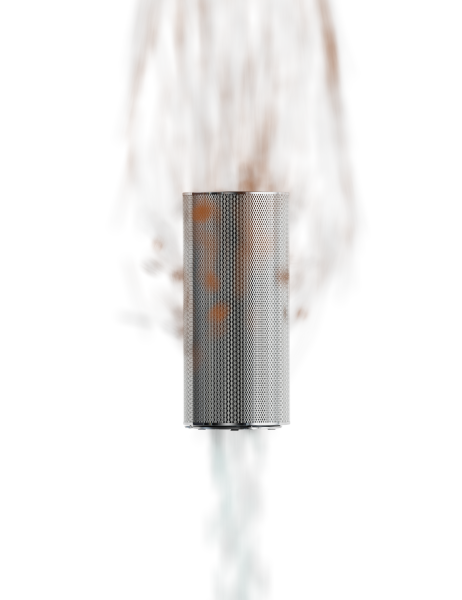

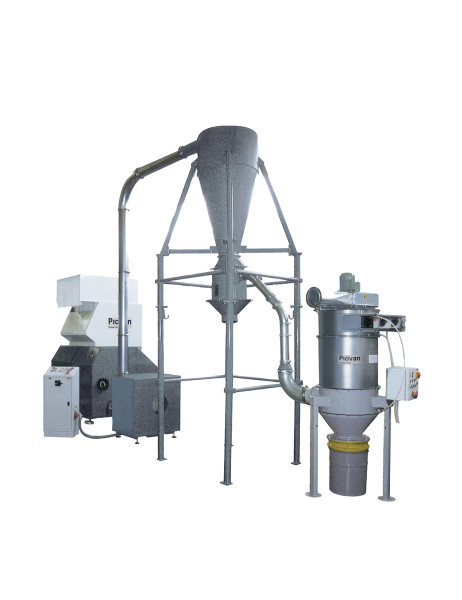

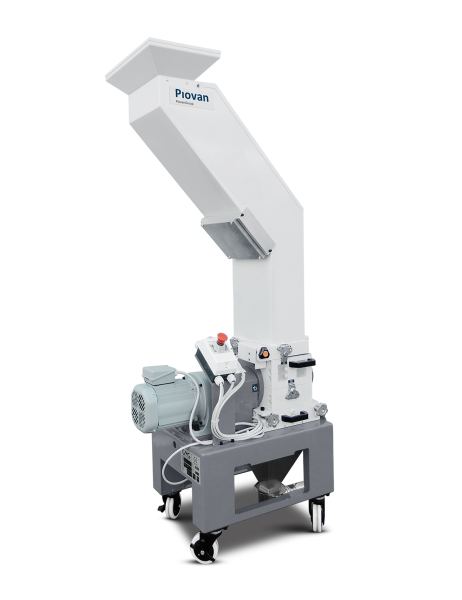

Granulation

Small, medium and large capacities, with the latest design for size reduction, granulation, recycling devices and accessories, represent the range of equipment of Piovan.

Flour cooling

Electrostatic coating

Storage

Sieving

Dosing

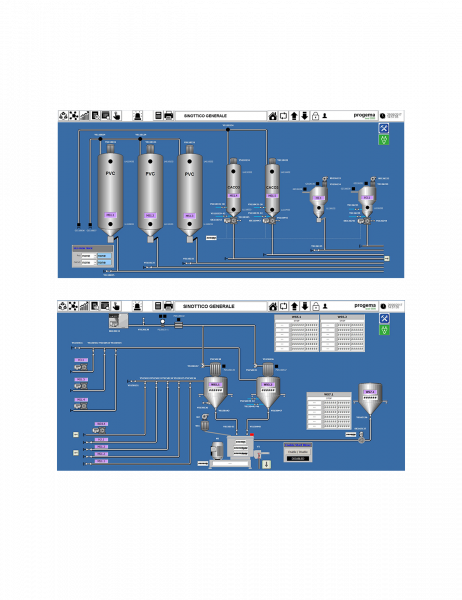

Supervision and Process Control

Dehumidification

Transport

Mixing

Sugar handling

Integrated Solutions

Flexcool solution can use ambient temperature to cool the processing equipment. Such a peculiar strategic feature makes Flexcool ideally suitable to serve sets of injection moulding machines having diverse characteristic, that is, in those working situations where different machines are required to operate at varying processing conditions of temperature, flow, pressure. Flexcool ensures the highest level of control, flexibility and energy efficiency.

Pet-Cooling Solutions

With specific skills and deep knowledge of the PET preform production process, we provide customised solutions able to satisfy the specific cooling needs of the PET preform sector.

Air-Cooled Chillers

Our air-cooled chillers provide the ideal cooling solution for a wide range of industrial applications related to the plastics processing and to the food industry.

Water-Cooled Chillers

Our water-cooled chillers provide high quality, operation efficiency, and energy savings for a wide range of industrial applications related to the plastics processing and to the food industry.

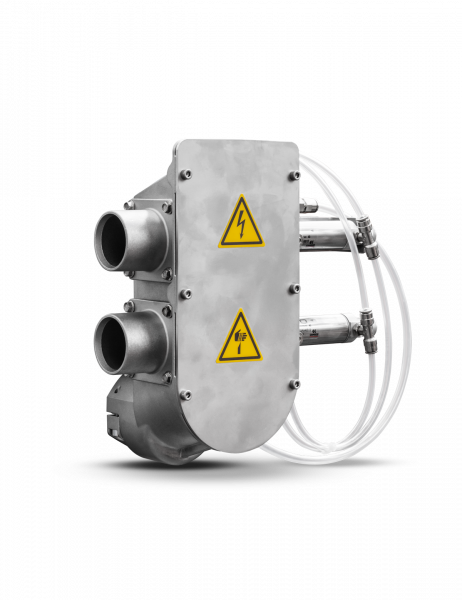

Machine-Side Chillers

Our product range includes a line of thermochillers which have the function to heat and cool the process circuit of injection and blow moulding machines utilized in the plastics processing. Available in the single or dual circuit versions, these machines provide maximum cooling yield with minimum energy consumption.

Temperature Controllers

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

Dry Coolers

Our dry coolers are the best answer to the needs of various industrial processes and applications where it is essential to constantly cool the fluid used for the heat exchange at a temperature greater than or equal to that of the external environment. Representing an effective alternative to cooling towers with low costs and low energy consumption.

Water and Environmental Treatment

Pump Stations

A very high attention and considerable importance is given to pumps, the devices that allow cooling and chilled water circulate throughout the circuit.

Accessories

Software

Piovan develops all software for the entire line of industrial cooling solutions.

News and Events

PIOVAN UNADYN AT PLASTICS TECHNOLOGY EXPO 2026

PIOVANGROUP AT PLAST EURASIA 2025

PIOVANGROUP AT PLASTICS RECYCLING SHOW INDIA 2025

PIOVAN UNDYN AT AMI PLASTICS WORLD EXPO NORTH AMERICA 2025

PIOVANGROUP AT GULFOOD MANUFACTURING 2025

Company Information

PIOVAN S.p.A. – Società a Socio Unico

Via delle Industrie, 16 - 30036 S. Maria di Sala (Venezia) - Italy

P.IVA 02700490275

C.F. e numero iscrizione al registro delle imprese di Venezia: 02307730289

Cap. soc. Euro 6.000.000,00 i.v.

REA n. VE 235320

Phone: +39 041 5799111

Fax: +39 041 5799244

Email: info@piovan.com

PEC: piovanspa@legalmail.it