Plastic recycling automation systems

Recycling of post-consumer plastics includes various processes involving dedicated equipment from the Piovan recycling products range. Also, converting of recycled plastic is very different from that of virgin material and therefore requires particular equipment as well.

Plastic recycling process: key challenges

Producers using PCR plastic must be able to adapt their plants to allow them to handle a material that is neither standard nor constant in terms of batch quality, as it may come from different sources. As a result, the chemical and physical characteristics may vary greatly as well as the presence of low boiling volatiles (VOC) and other contaminants (NIAS).

Reduction in the useful life of the equipment Process instability Presence of potential contaminants in the final product

From size reduction to deodorization to production traceability: a complete product range

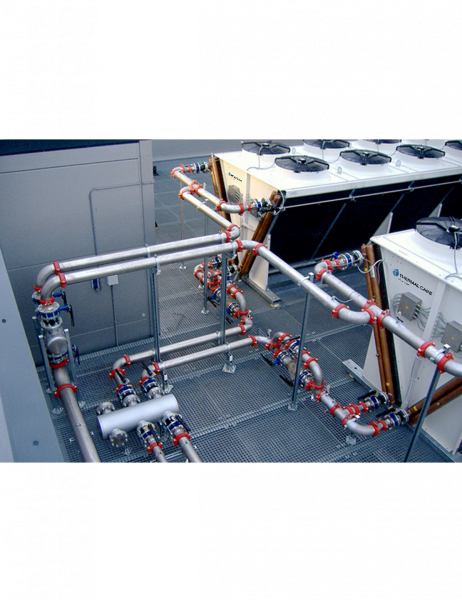

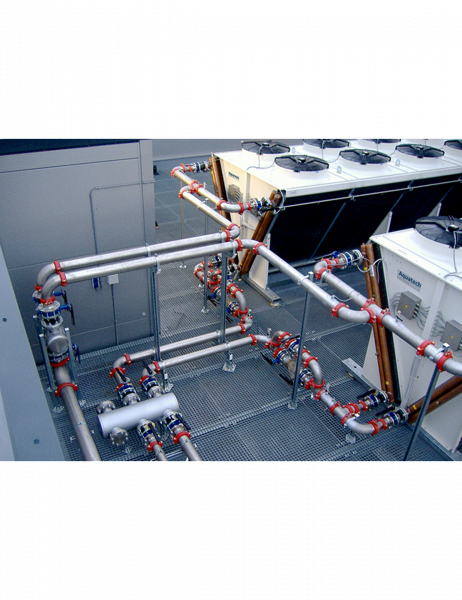

The PiovanGroup offers unique solutions for the treatment and production of recycled plastics (PET, PP, HDPE - but not only these), in different forms such as granules or flakes, which guarantee production quality and maximum equipment utilisation.

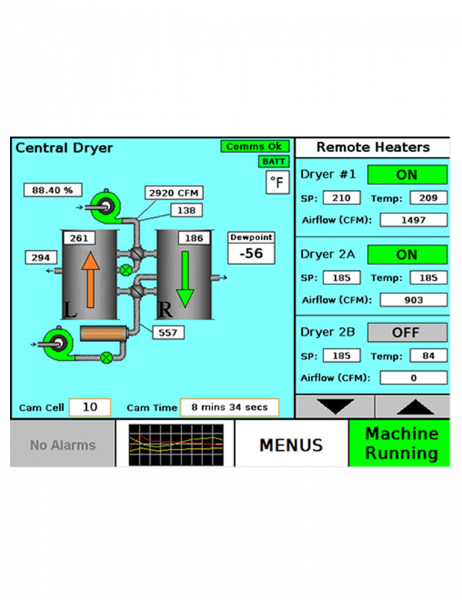

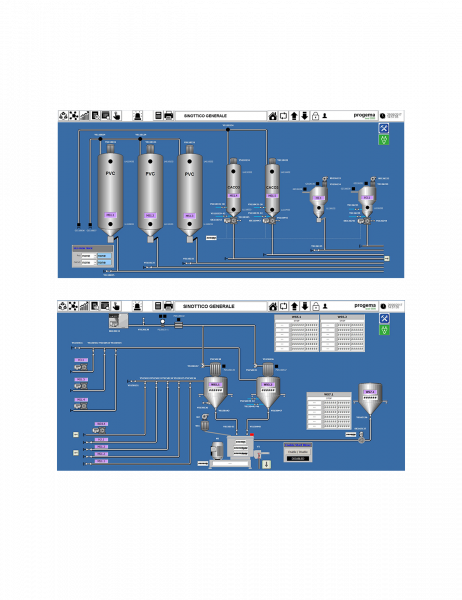

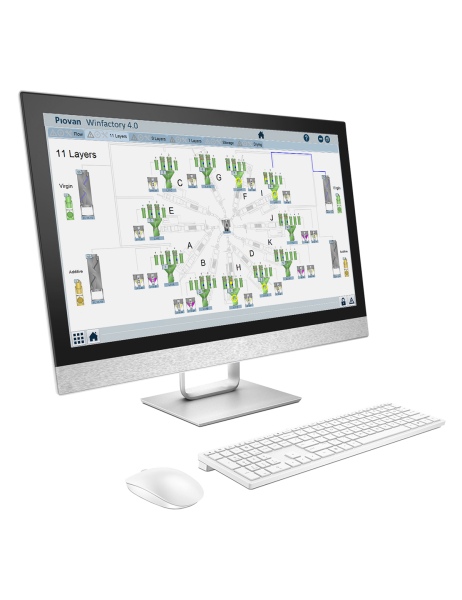

The offer includes conveying systems, shredders and grinders for the size reduction of the material to be recycled, crystallisers to crystallise materials in the amorphous state and dehumidifiers and hot-air dryers. The PiovanGroup also produces deodorisation systems, solutions for the condensation of low-boiling contaminants and analysis instruments to detect the presence of contaminants in real time. Finally, it develops software to support the quality control system by tracking of production processes and products parameters, storing data for years and interfacing with the company ERP.

The use of Piovan machineries, specific to the treatment of recycled plastic, contributes to an increase in the quality of the final product and at the same time, controls scrap, energy consumption and costs.

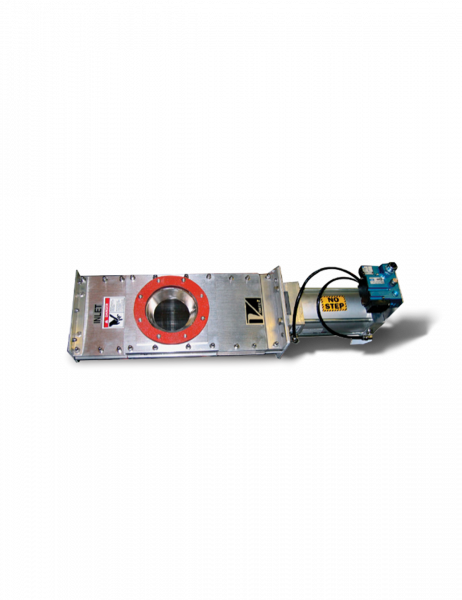

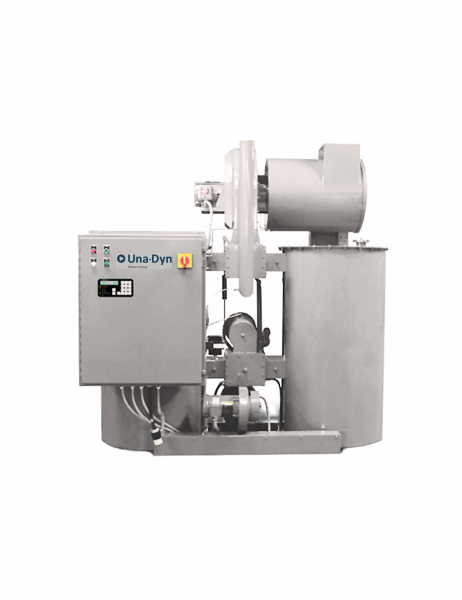

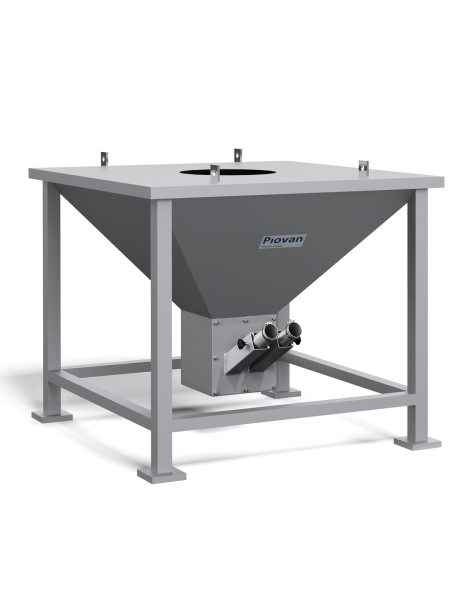

Storage Big-Bag Station

The practical unloading station is suitable for big-bag of granules or flakes, with a capacity up to 2,000 kg. It can be equipped with level sensors on the storage bin, extracting auger or electromechanical vibrators. On request, the collecting bin is available in stainless steel.

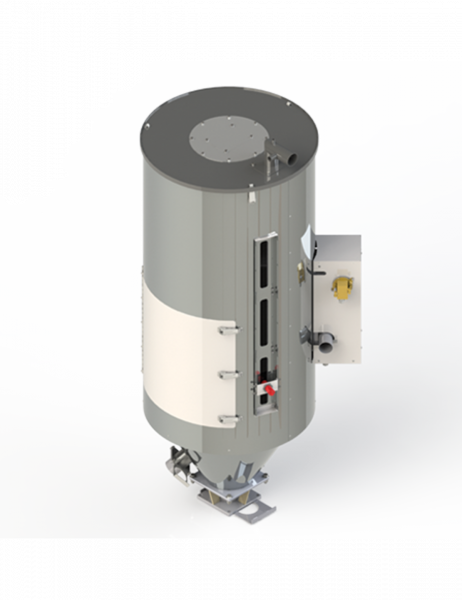

Storage GS Series

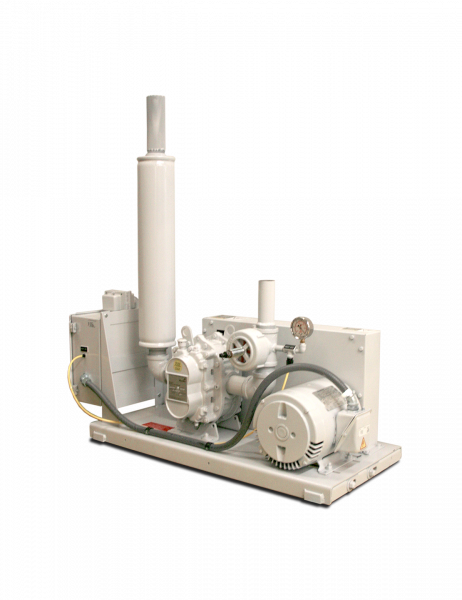

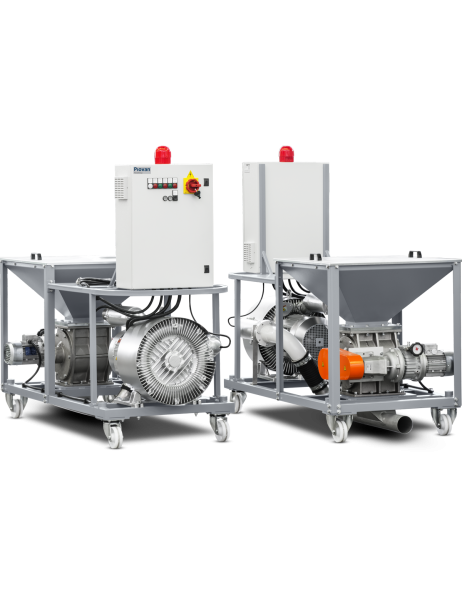

Conveying system for high throughput and long distances, suitable for silos loading. In case of manual filling, a practical grid to avoid lumps of material is available on request. In case of multiple destinations, the management of diverting valves can be integrated in the control.

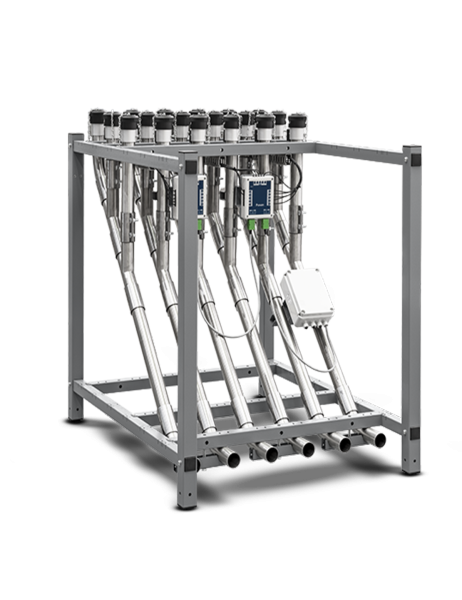

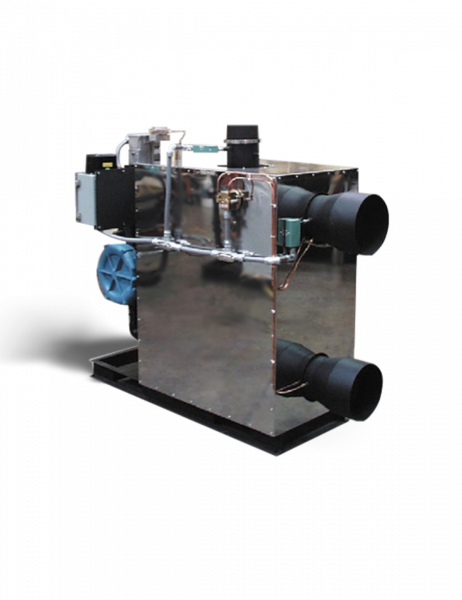

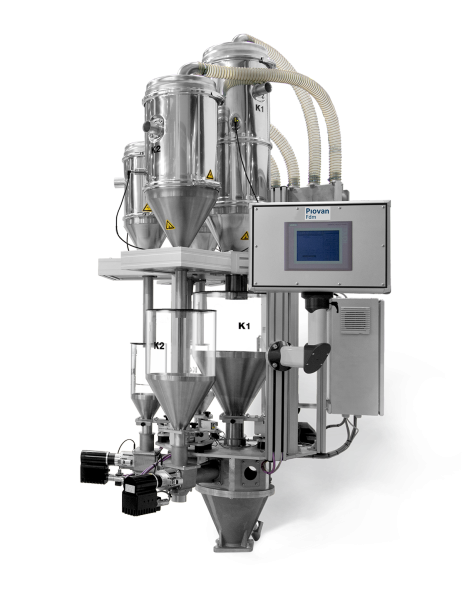

Dosing MDW

Available for flakes and high temperatures, the MDW gravimetric batch blenders can dose and weigh up to 8 materials. The microprocessor control assures high execution speed, precision and simple setting of the unit. The MDW blenders guarantee quick material change and simplified cleaning operations.

Storage Textile silos

Reinforced high resistant textile silos are suitable with materials with PSA up to 0.6 kg/dm3 as standard. The solution is characterised by antistatic, anti condensation and anti dust behaviours. The silo roof section is made by a filtering textile for a practical and safe evacuation of air during the pressure loading.

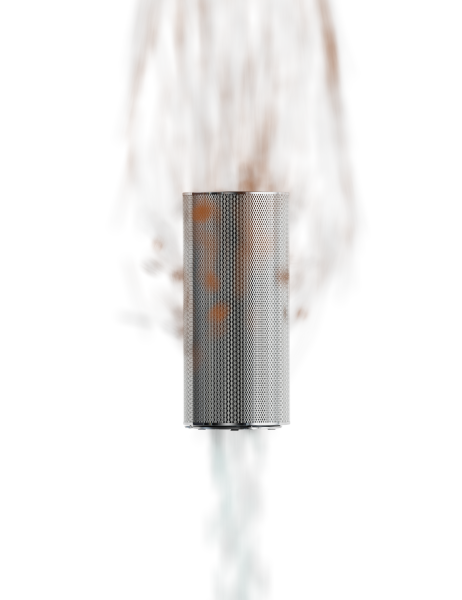

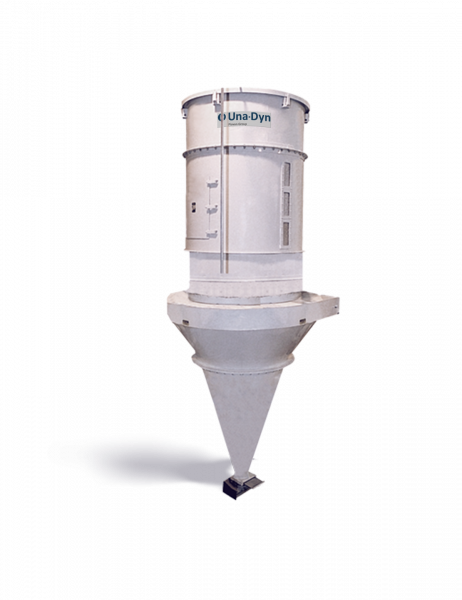

Storage Silos

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.