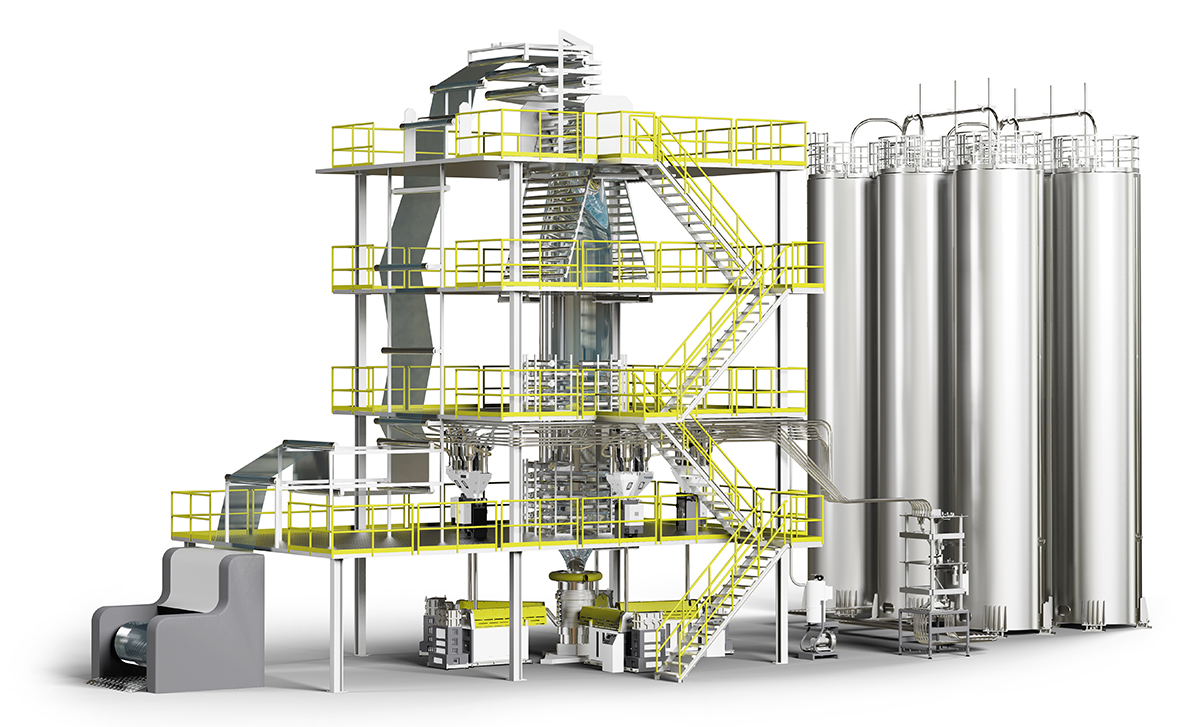

Automation systems for flexible film production

Maximise the factory productivity with full automation for raw materials distribution and extrusion control.

Extrusion of Flexible Film is a market in continuous evolution and over the years it has become a process where the care of all details related to manufacturing is an essential feature to be competitive. Whatever the application sector, food packaging, industrial, hygiene or agricultural film, PiovanGroup is the ideal partner with which to develop the right solution.

Complete product range for blown, cast and bi-oriented film extrusion lines

PiovanGroup design, manufacture and install machinery and complete turn-key plants to maximise the productivity of blown, cast and bi-oriented film extrusion lines.

The long co-operation with the main leading OEMs in the Extrusion of Flexible Film has allowed the Group to develop extremely reliable solutions suitable for this high technological demanding sector.

The process efficiency is our main target to maximise productivity, even with frequent recipe changes, whilst minimising the possibility of human error and reducing waste. Our expertise involves all the most relevant processes that contribute to high quality film manufacturing.

Piovan's range of products includes, among others, storage silos, daily bins, big bag and octabin unloading units, pressure, dense phase and vacuum pneumatic feeding systems, de-dusting units, automatic and manual distribution systems, dryers, gravimetric batch and gravimetric continuous blenders, film weight and thickness control, manual and automatic air cooling ring, process control and supervising software.

Storage Silos

Large diameter silos offer with great attention to functional and aesthetics for outdoor installation. Suitable for granules, flakes or powders, the Piovan silos have specific geometries and devices according to the materials to store, such as outlet air filters, extraction systems for high friction polymers, measurement solutions like load cells and protection systems for potentially explosive atmospheres. These silos are compatible with a wide range of loading methods like truck pumps, sea containers with bags, high pressure blowers for dense or semidense phase conveying systems.

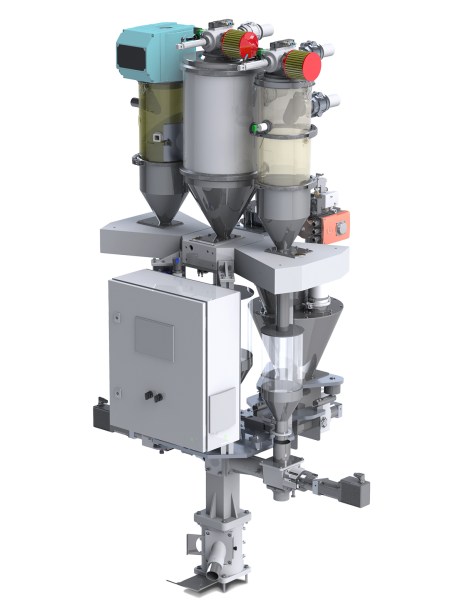

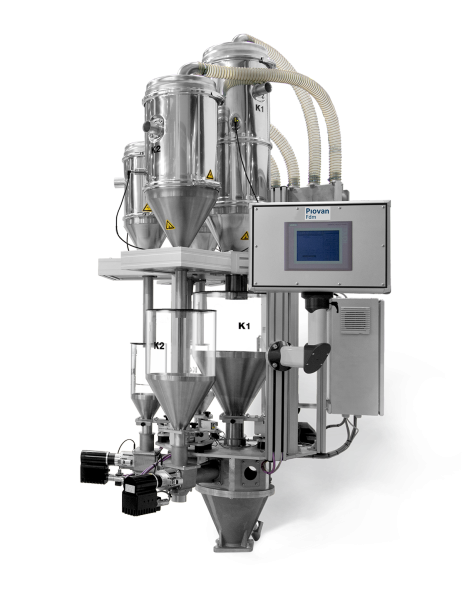

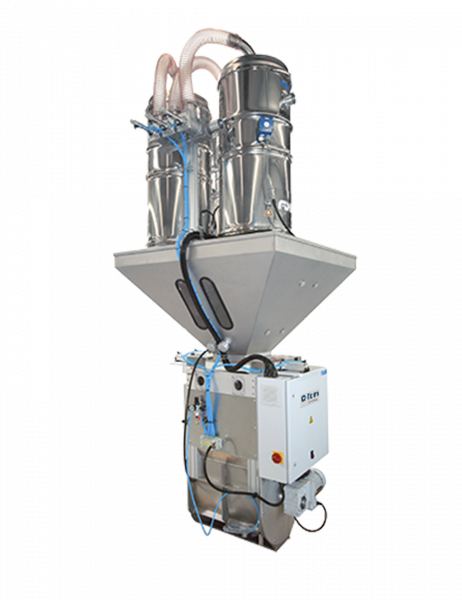

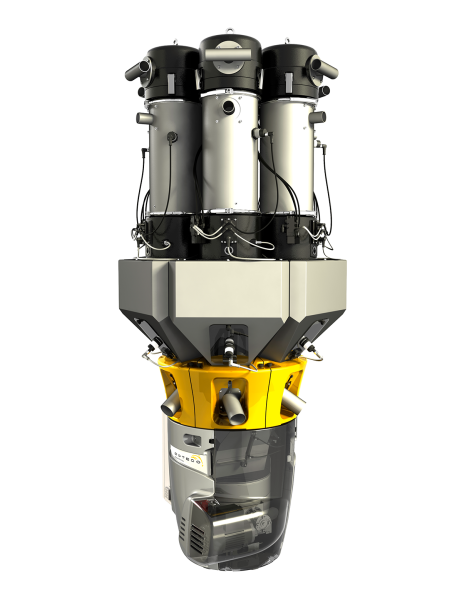

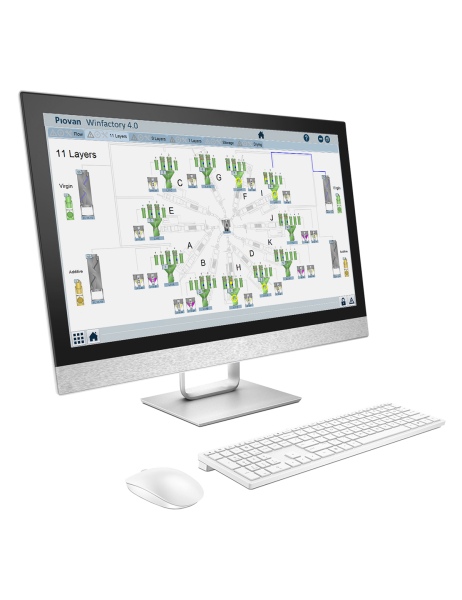

Dosing Quantum E

Quantum E is the Piovan gravimetric batch blender for dosing and controlling the extrusion process. Its control is by means of latest-generation PLC, with colour touch screens up to 15”, for total extrusion control in real-time. Quantum E is very versatile thanks to 8 dosing stations and has been designed for total process traceability especially in conjunction with Winfactory 4.0. The particular design of the patented spherical mixer, with double load cells, assure homogeneous and precise blend of the various ingredients.

Conveying Easylink+

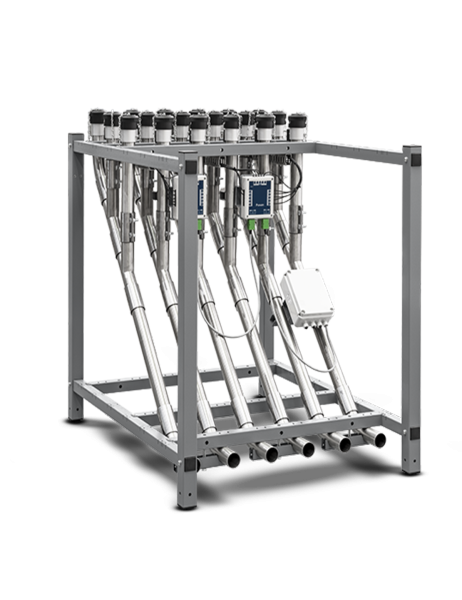

Easylink+ is the Piovan automatic coupling station able to manage up to 60 inlets/outlets with pipe size from 40 to 76 mm with minimum footprint. Designed for easy maintenance, it is totally safe for the operators both during regular functioning and service activities. The geometries, the advanced cleaning systems and the wear resistant materials assure the constant production quality in most demanding conditions. Easylink+ is available with supporting frame for floor or mezzanine installation.

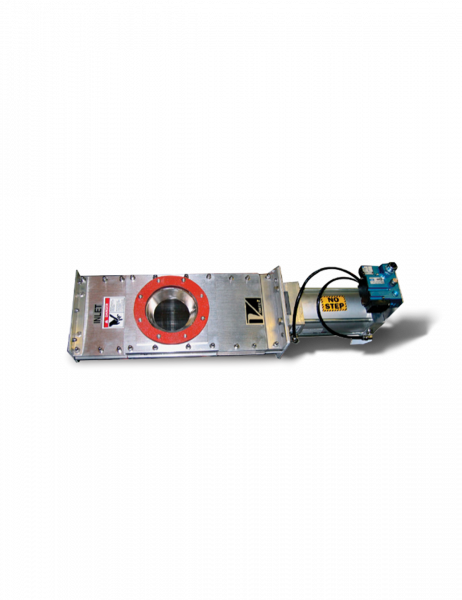

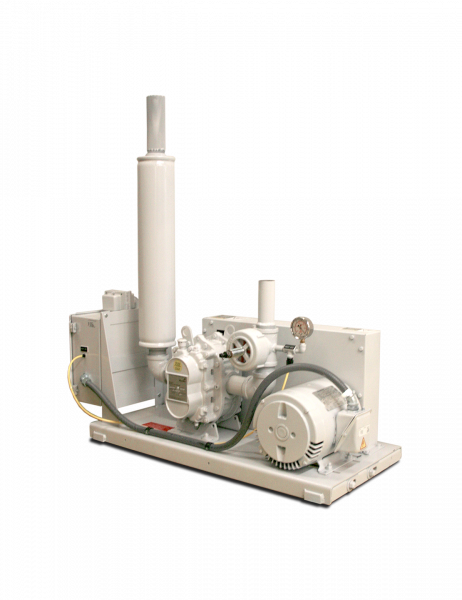

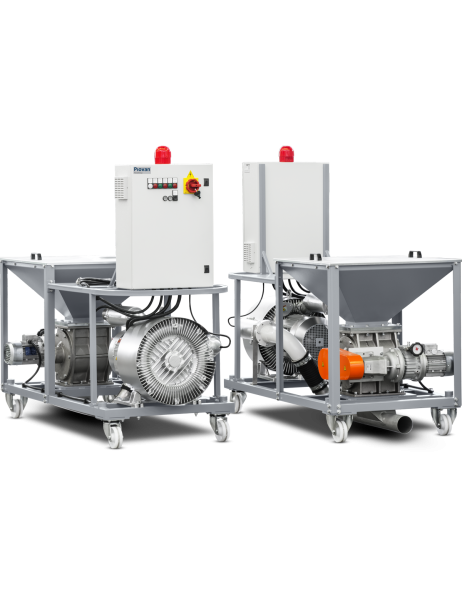

Conveying F Series

The F series vacuum units are characterised by low noise level, up to 75 dB(A), and compact footprint. The F series vacuum units are available in two versions (side channels or claw pump): this allows always the best technical solution for the specific need. Such design makes them suitable for standalone installation beside the IMM and centralized feeding systems or to feed systems with medium to high pressure losses and high kg/h throughput.

Featured Products

Feeding & Conveying

The range of Piovan solutions spans from stand-alone single material loaders to central multiple material systems.

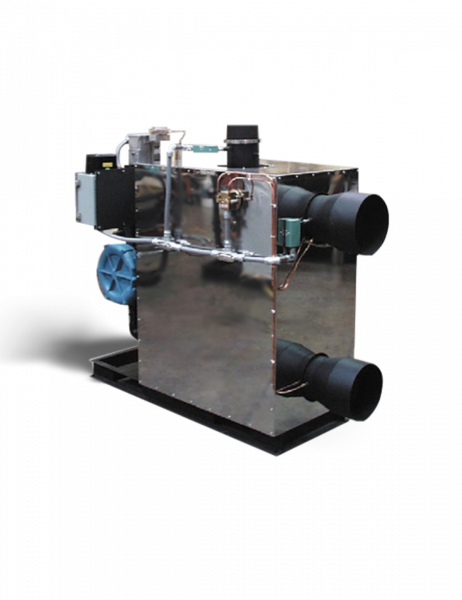

Drying & Dehumidifying

Broad selection of technologies to perform the drying process in the best condition possible for the raw material.

Dosing & Blending

Volumetric, gravimetric, loss-in-weight, continuous or batch, are the technologies implemented in the series of blenders and dosing units of Piovan.

Temperature control

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

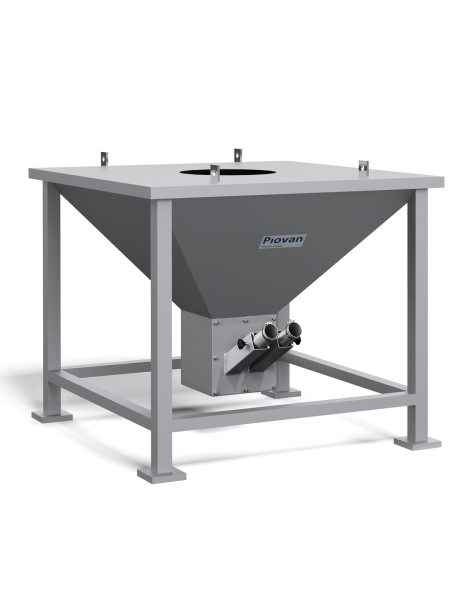

Storage

Wide range of solutions that includes from the small movable storage silos on wheels, up to the external silos to stock tonnes of material. The solutions can be totally tailor made on customer request.

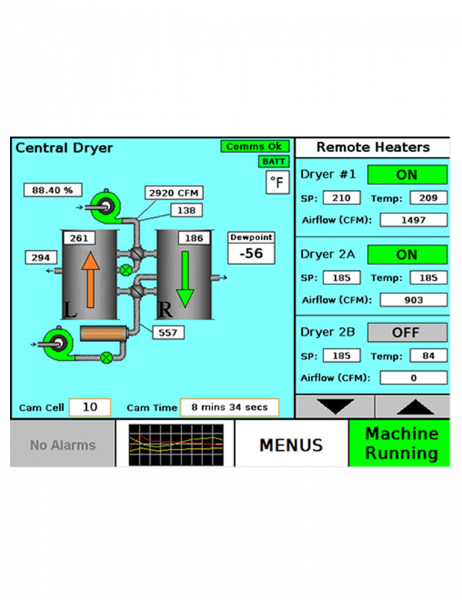

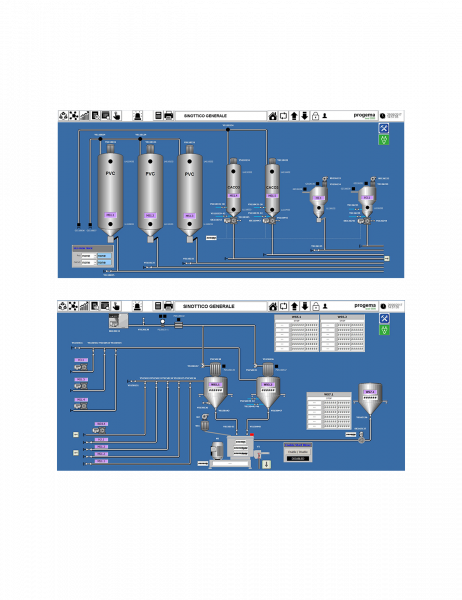

Software & Control systems

Process integration and control systems are key to maximizing efficiency and achieving high performance.

Lab-tech

The simplest way of measuring AA levels in PET preforms. The Piovan Lab-Tech range allows utmost production monitoring, by providing real time analysis of acetaldehyde content in the PET preforms.

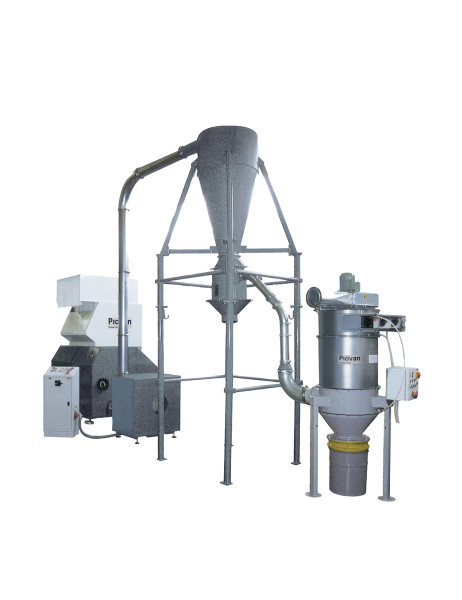

Granulation

Small, medium and large capacities, with the latest design for size reduction, granulation, recycling devices and accessories, represent the range of equipment of Piovan.

Flour cooling

Electrostatic coating

Storage

Sieving

Dosing

Supervision and Process Control

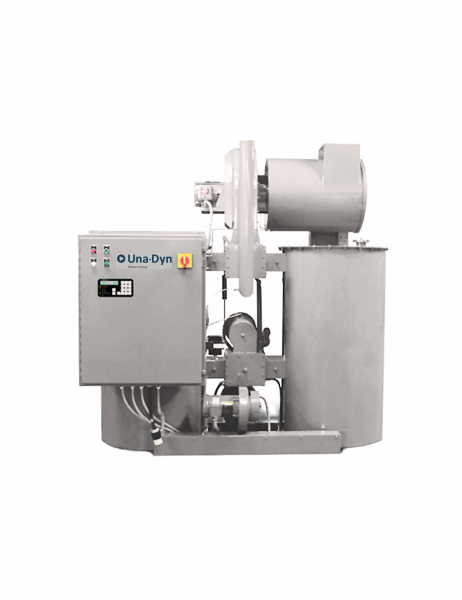

Dehumidification

Transport

Mixing

Sugar handling

Integrated Solutions

Flexcool solution can use ambient temperature to cool the processing equipment. Such a peculiar strategic feature makes Flexcool ideally suitable to serve sets of injection moulding machines having diverse characteristic, that is, in those working situations where different machines are required to operate at varying processing conditions of temperature, flow, pressure. Flexcool ensures the highest level of control, flexibility and energy efficiency.

Pet-Cooling Solutions

With specific skills and deep knowledge of the PET preform production process, we provide customised solutions able to satisfy the specific cooling needs of the PET preform sector.

Air-Cooled Chillers

Our air-cooled chillers provide the ideal cooling solution for a wide range of industrial applications related to the plastics processing and to the food industry.

Water-Cooled Chillers

Our water-cooled chillers provide high quality, operation efficiency, and energy savings for a wide range of industrial applications related to the plastics processing and to the food industry.

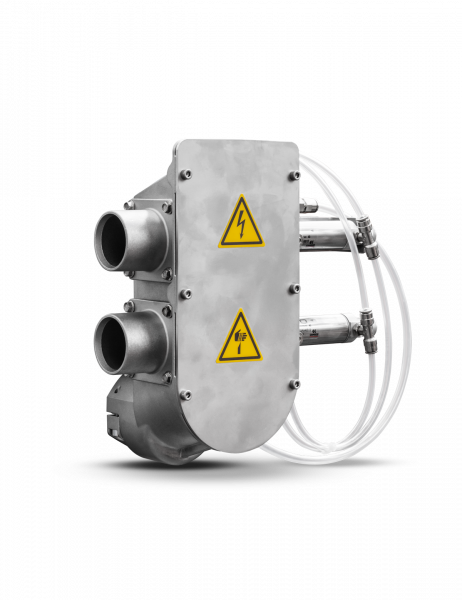

Machine-Side Chillers

Our product range includes a line of thermochillers which have the function to heat and cool the process circuit of injection and blow moulding machines utilized in the plastics processing. Available in the single or dual circuit versions, these machines provide maximum cooling yield with minimum energy consumption.

Temperature Controllers

Efficiency of heat exchange and reliability of operation characterise our range of temperature control units.

Dry Coolers

Our dry coolers are the best answer to the needs of various industrial processes and applications where it is essential to constantly cool the fluid used for the heat exchange at a temperature greater than or equal to that of the external environment. Representing an effective alternative to cooling towers with low costs and low energy consumption.

Water and Environmental Treatment

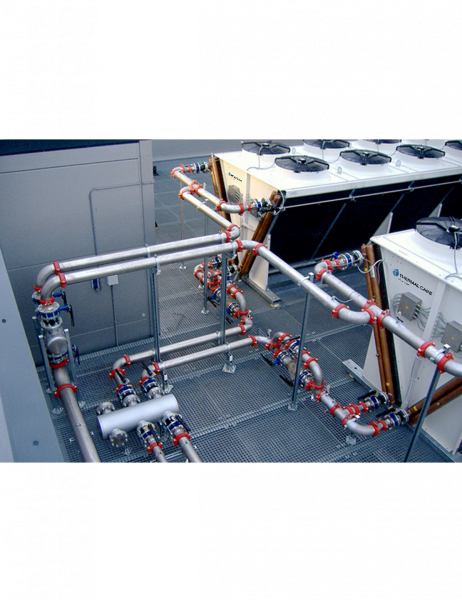

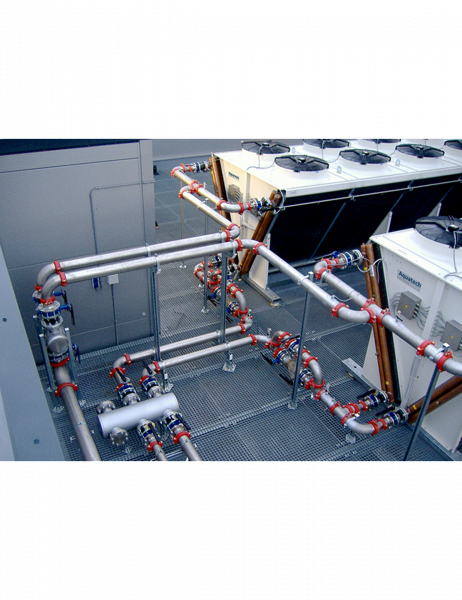

Pump Stations

A very high attention and considerable importance is given to pumps, the devices that allow cooling and chilled water circulate throughout the circuit.

Accessories

Software

Piovan develops all software for the entire line of industrial cooling solutions.