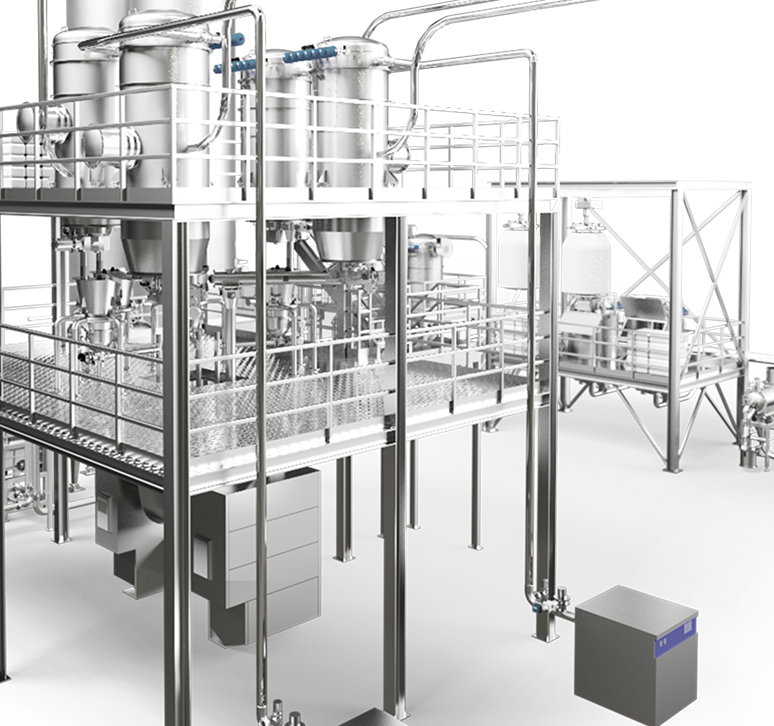

Turnkey chocolate handling systems

Chocolate storage and transport systems

PiovanGroup provides specific and highly customised solutions for the storage and transport of chocolate, guaranteeing maximum attention to detail. Specifically, the geometry and accurate internal surface finish of the silos, equipped with internal stirrer, pumps and load cells, ensure the easy flow of chocolate. Furthermore, double jacket conveying solutions guarantee the conservation of the correct viscosity and maximum safety during the transport of the food ingredient. PiovanGroup also designs and manufactures machinery for the addition of additives and inclusions, to add to chocolate in a controlled and precise manner.

The consolidated experience of the Group in the confectionery sector, combined with a capillary technical assistance service, ensures constant proximity to the customer worldwide. All Piovan Group machines for chocolate processing are characterised, moreover, by easy access and maintenance and by guaranteeing maximum levels of safety.

Our chocolate making equipment

Storage, transport, dosing and sieving are just some of the food ingredient processing stages in which Piovan Penta and Piovan Fea, the Piovan Group companies specialising in automation systems for the processing of food ingredients, operate.

Flour cooling

Electrostatic coating

Electrostatic coating

Storage

Storage

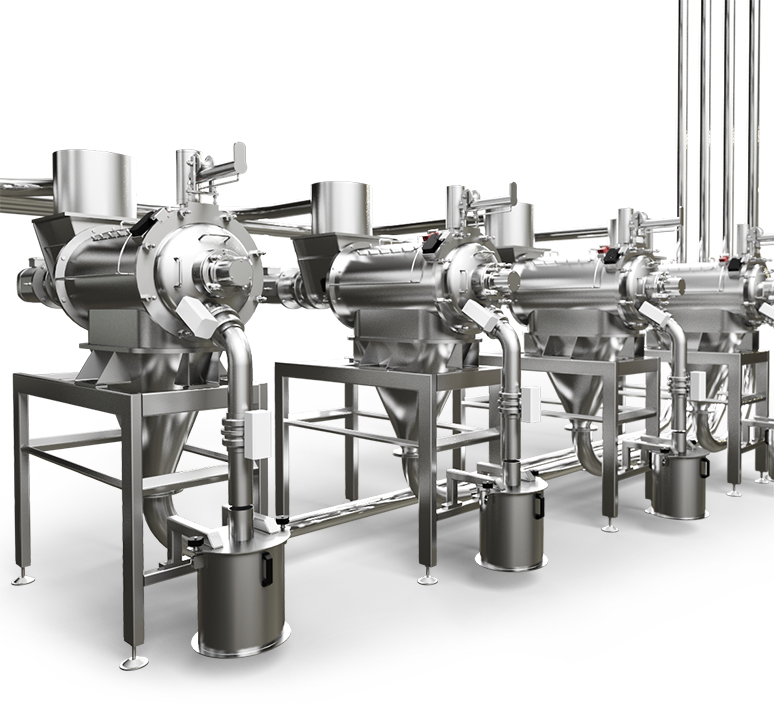

Sieving

Sieving

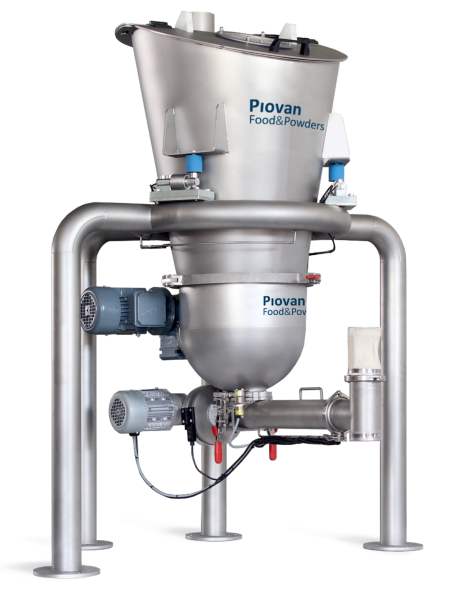

Dosing

Dosing

Supervision and Process Control

Supervision and Process Control

Dehumidification

Dehumidification

Transport

Transport

Mixing

Sugar handling

Sugar handling

More in detail, it designs and manufactures machinery for ambient air drying, conveying, shredding, storage and dosing.