Choose the country or territory you are in to see local content.

Industry Expertise applied to the production of biscuits and bakery products

In the food industry, including applications related to the production of baked goods such as croissants, cakes, biscuits and crackers, it is crucial to ensure the highest quality processes without altering the properties of the product and at the same time ensure maximum hygiene to prevent any external agents and moisture that can come into contact with the product.

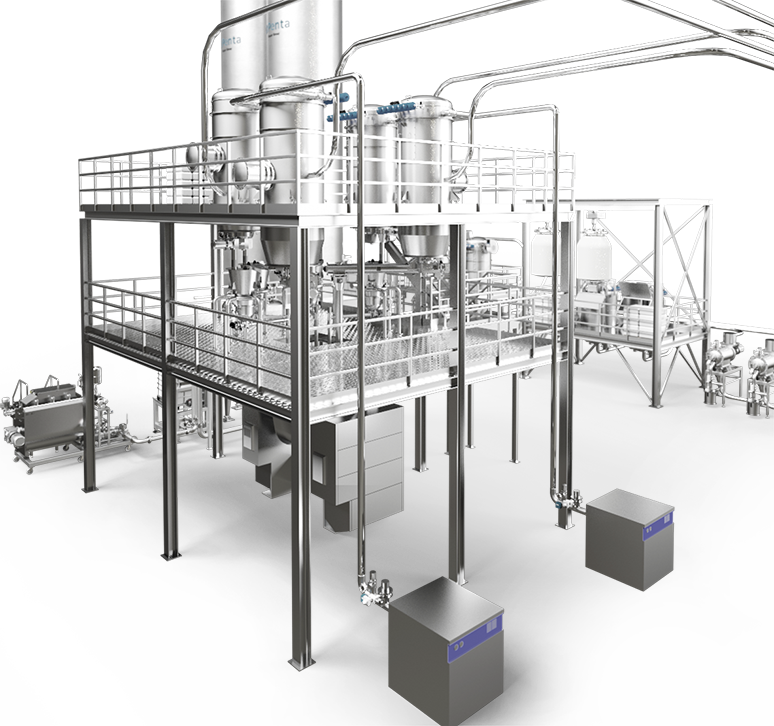

Piovan Group is able to provide customised turnkey solutions designed to meet the production requirements of the customer. To cite just a few examples, our customers include producers of all the main types of biscuits such as filled, rolled, wire-cut and cast biscuits.

The PiovanGroup designs and manufactures specific preparers for the production of products such as creams and caramel, suitable for powders, liquids and fats. Specifically, PiovanGroup offers the possibility to have a highly customised preparer designed according to the needs of the customer and the product to be made. The Piovan preparators can also be fed with a premix of powders ready to be used in the recipe.

Spheriko is the innovative dosing unit that has been specifically developed and manufactured to satisfy the requirements of the food industry. Suitable for handling food powders and additives, this weighing system features quick and simplified connections that make it extremely easy to clean, thus eliminating the need for advanced technical skills.

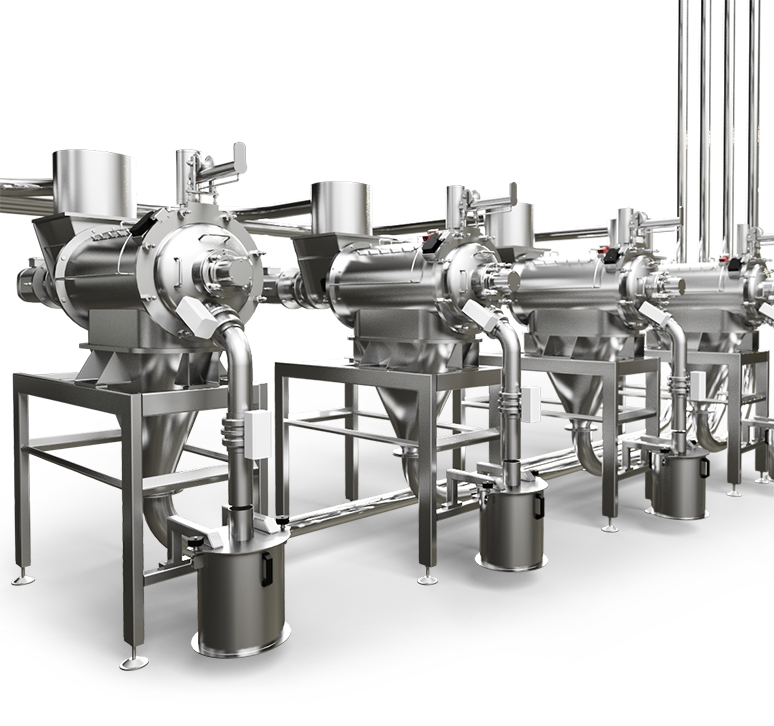

PiovanGroup designs and manufactures a range of industrial sieves to filter powders and food ingredients of different particle sizes, such as flour, cocoa and sugar. The sieving frame of these units consists of a very robust perforated, stainless steel plate. Moreover, Piovan sieve systems are easy to inspect and clean.

The objective of bakery products manufacturers is to ensure that the finished product is of consistent quality all year round, regardless of outside temperatures but also of the geographical location of the production plant.

Process air must be treated, filtered and dried before coming into contact with the product. The PiovanGroup proposes a solution with air technology to reach the lowest temperatures required by the customer in a simple, controlled and efficient way and guarantee the highest quality of the dough. This solution is suitable also for all the processes that use Gluten Free flours.

PiovanGroup manufactures both stations for unloading bags and big-bags separately and integrated solutions able to manage both. The PiovanGroup bag and big-bag unloading station are equipped with a hoist and a bag shaking system. Through tensioning and shaking the big-bags are always emptied correctly and in the required time, even in the case of products that are difficult to handle.

PiovanGroup designs and manufactures silos in stainless steel or aluminium alloy for the storage of powder or liquid materials, such as flour, sugar, glucose and chocolate. The Group produces ATEX certified monolithic silos. The silos ensure automated conveying operations and can be equipped with level sensors, load cells and special filtration systems.

The Group also designs and manufactures fully customised, automated big-bag solutions in controlled atmosphere environments.

The PiovanGroup provides raw material shredding solutions to eliminate lumps inside silos, bags and big-bags. The Piovan lump-breaker for food powders guarantees maximum safety and simplified inspection and cleaning operations. In particular, the single-shaft sugar lump-breaker designed by the Group ensures that any lumps are shredded by a rotating component with blade tools.