Innovating for nearly a century

Generating value for the customer through Innovation has been our strategic goal since the very beginning. Through research, technological development and constant exploration of new paths, we have become a market leader.

0

R&D ENGINEERS

0.0%

R&D INVESTMENTS

Nowadays, the Group’s R&D division employs 316 specialists dedicated to the Engineering & Innovation.

It is a team that is constantly growing, thanks also to recruitment policies aimed at including highly qualified talent to develop innovative solutions that create added value for the Group.

Co-engineering & Innovation

Driving excellence in technology and quality

PiovanGroup R&D works closely with Customers, Marketing and Sales to develop new technologies and constantly improve product quality and production process efficiency. Our relationships with leading manufacturers of processing machines - such as injection moulding machines, blow moulding machines and extrusion lines - , with research laboratories and university institutes, help us to create new customised solutions to fully meet specific customer requirements.

Global experts with deep process knowledge

Dense network of experts worldwide

PiovanGroup designers and engineers are experts in different application fields of plastics and food, accustomed to face and solve problems related to the different production techniques and properties of polymers and ingredients.

The teams of specialists are able to deal with the specificities of each type of final products and provide equipment suitable to handle even the latest materials anywhere in the world.

The teams of specialists are able to deal with the specificities of each type of final products and provide equipment suitable to handle even the latest materials anywhere in the world.

Research & Development

The core of PiovanGroup's pioneering innovation

PiovanGroup attributes a role of strategic importance to the research and development of products and new solutions, necessary to maintain its leadership position in the markets. The focus of the R&D team is the creation of innovative solutions for the treatment of recycled materials and the update of the core offer. Each production site has a specific R&D department that reports functionally to the headquarter to ensure proper technology transfer.

0+

PATENT

FAMILIES

0+

Industrial property titles

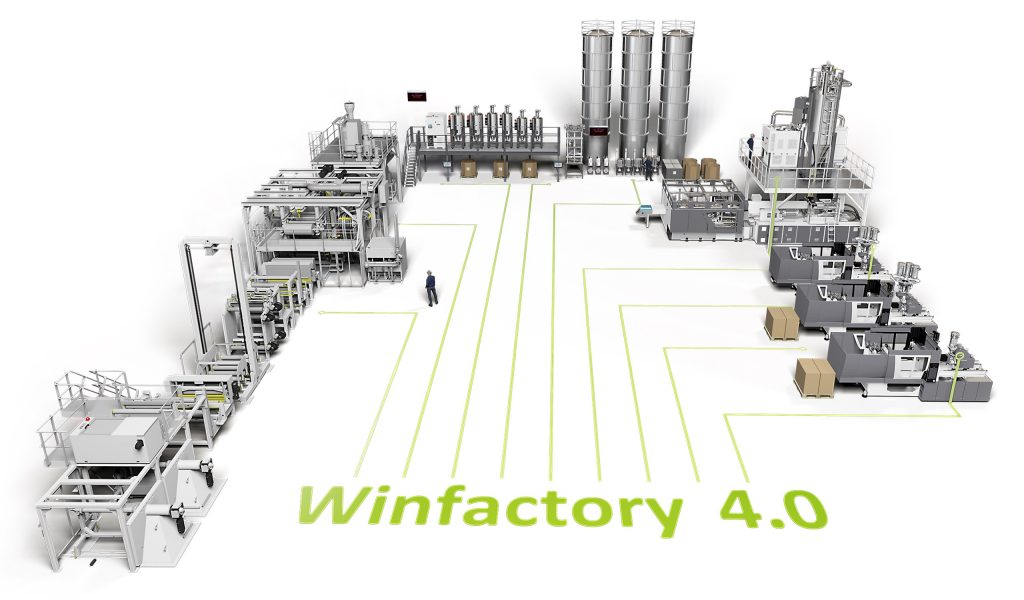

Integrated, high efficiency engineering solutions

High automation, efficiency and robustness of processes are daily requirements in the market where the Group operates.

This is why there are dedicated resources and a constant commitment to the development of proprietary supervision software necessary for Industry 4.0 or IIoT (Industrial Internet of Things).

The Group's Research and Development strengths

FULL KNOWLEDGE

of different production processes

SHARING

of the know-how between professionals and young talents

GLOBAL PRESENCE

with locally developed solutions

Innovation and cutting-edge technology are among the Group's key success factors.

Particular attention is therefore paid to the competitive advantage achievable in terms of intellectual property, as well as to the creation and management of a portfolio of trademarks, patents and licences.

Particular attention is therefore paid to the competitive advantage achievable in terms of intellectual property, as well as to the creation and management of a portfolio of trademarks, patents and licences.

In 2024, PiovanGroup continued to invest in its patent activity: 125 patent families, 22 of which relating to the circular economy or in any case related to recycling.

Constantly evolving innovation

2023

2022

2021

2020

2019

2018

2016

2015

2014

2010

2008

2022

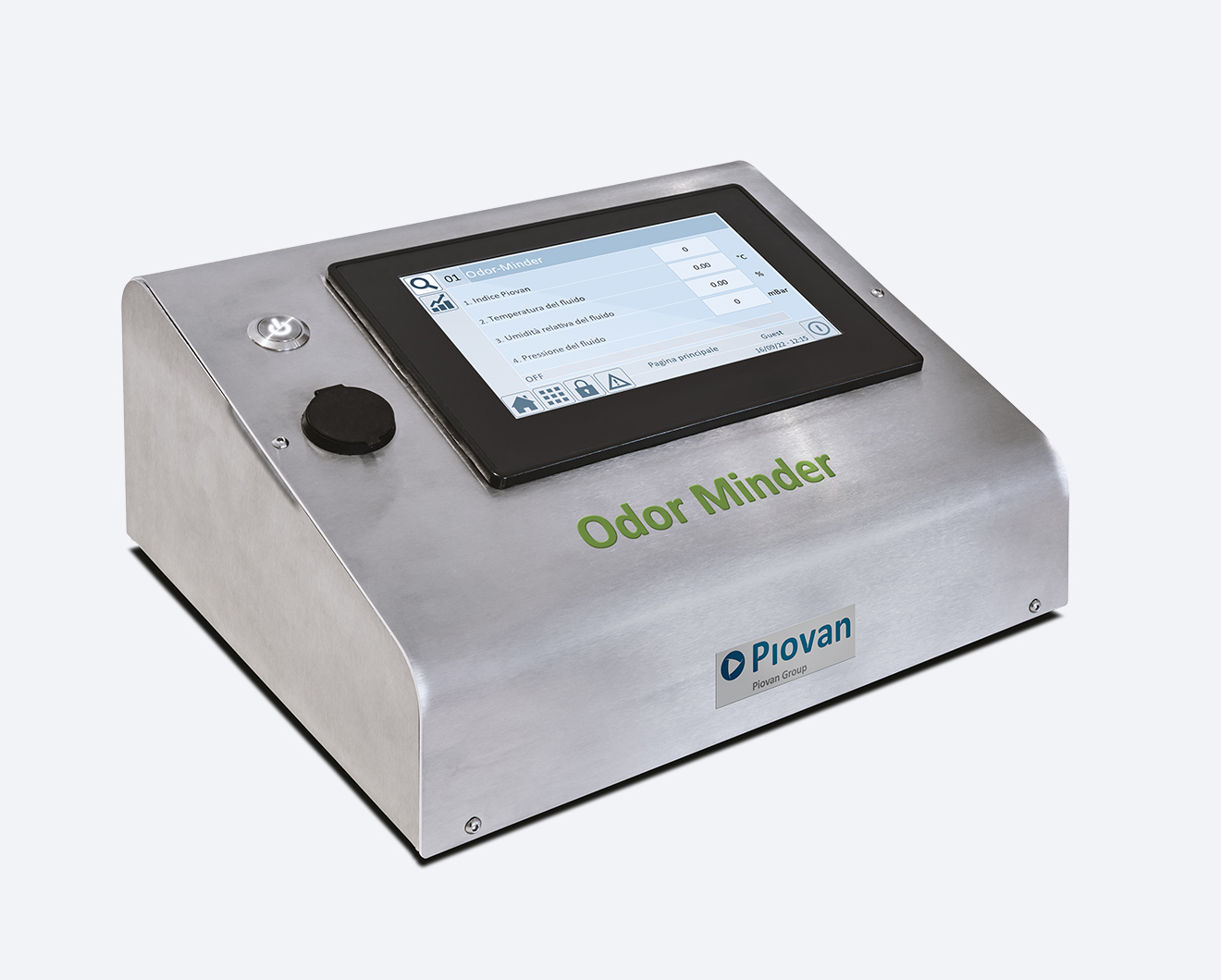

Odor Minder

Compact in-line electronic nose to verify the effectiveness of the post-consumer plastic deodorisation.

2021

Solution for condensing low boiling point substances released from plastic pellets during the drying process.

2021

SoftBoost

Heats rPET granule to the core without stressing it and saving energy.

2021

Vulkano

Portable instrument for measuring the presence of VOCs in process air.

2021

Easypure

Deodoriser that strips critical volatile substances, which generate unpleasant smells, from post-consumer plastic during its recycling process.

2020

Analysis instrument that detects the presence of benzene and certifies the good quality of the product.

2020

SprayStay

Technology for the electrostatic coating of baked products, snacks and chocolate.

Our Quality Policy

PiovanGroup is constantly committed to fulfill customer expectations by continuously improving its products and production processes.

The Group's ISO certification, together with lean methodologies, constantly monitored KPIs and supplier audits guarantee consistent performance, production traceability and a focus on customer value.

The Group's ISO certification, together with lean methodologies, constantly monitored KPIs and supplier audits guarantee consistent performance, production traceability and a focus on customer value.

Download Quality Policy