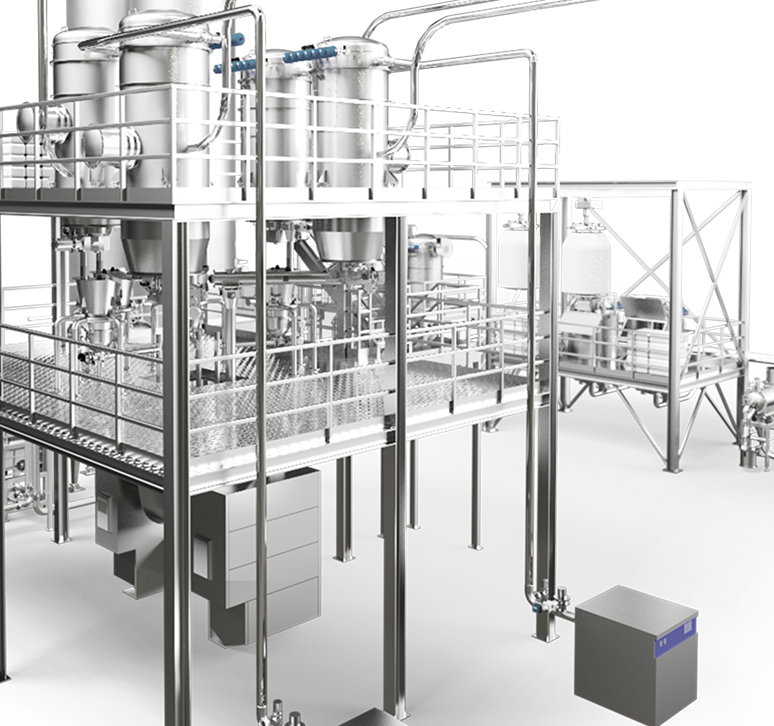

焦糖处理交钥匙系统

粘性和复杂产品处理的长期经验

焦糖是一种糖果,由于蔗糖和其他成分(如牛奶、盐、乳化剂、碳酸氢盐和葡萄糖)的烹煮,具有较高的粘度。 更详细地说,在焦糖的生产中,糖被加热到熔点。 这种热处理过程会去除水分以及使甜味物质变成焦糖,从而产生固体无定形物质。

焦糖生产系统

焦糖的工业生产要求最终产品的化学和物理特性,如 pH 值、比重、颜色和稠度,无论外部环境条件如何,全年都保持不变。

百旺集团工程师和技术人员的专业知识和现场经验, 是我们提供全球范围内支持的保证。

百旺集团工程师和技术人员的专业知识和现场经验, 是我们提供全球范围内支持的保证。

过程一致性

施工前测试

全球分布性

我们的工业焦糖生产技术

储存、除湿、运输、碎片破碎和筛分只是百旺集团能够运作的部分食品原料加工阶段。特别是Penta和Fea是集团中专门从事食品粉末、颗粒和液体产品处理的自动化系统的公司

Flour cooling

Electrostatic coating

存储

存储

FLEXIBILITY IN DESIGN AND CONSTRUCTION

Storing raw materials while maximising safety levels and minimising the risk of contamination is crucial in all food processes. PiovanGroup designs and manufactures silos in stainless steel or aluminium alloy for the storage of powder or liquid materials, such as flour, sugar, glucose and chocolate. The Group produces ATEX certified monolithic silos.

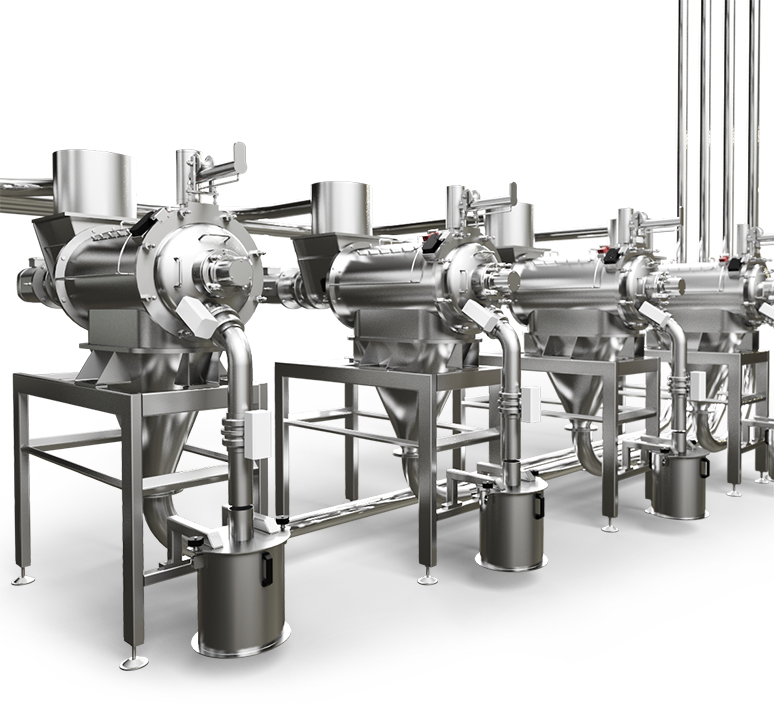

Sieving

Sieving

ROBUST, EFFECTIVE AND EASY TO INSPECT SIEVES

Industrial sieving of food ingredients is essential to ensure the quality of the finished product. This process ensures the correct size of the product in transit and eliminates any contaminants or impurities larger than the sieve drum screen itself.

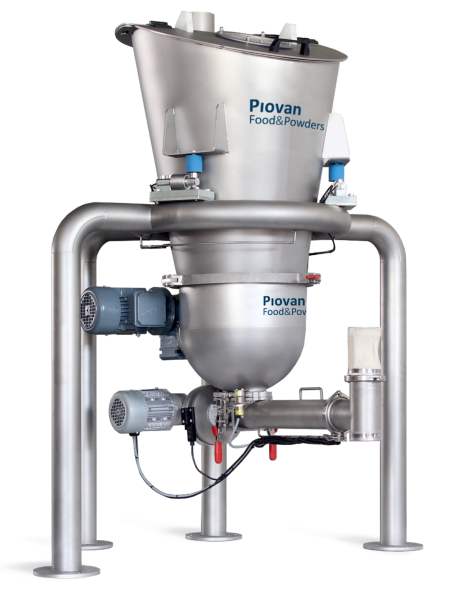

Dosing

Dosing

ACCURATE DOSING AND EASY CLEANING

In food ingredient handling processes, accurate dosing of powders and granular products is essential. PiovanGroup designs a range of loss-in-weight dosers that guarantee absolute dosing precision thanks to a spherical arc. These dosing machines provide, with reference to the relevant recipe, the correct quantity of raw material that can be mixed or directly discharged into the primary operating machines. It is also possible to create a premix between different ingredients, through continuous dosing.

Supervision and Process Control

Supervision and Process Control

PLANT MANAGEMENT AND SUPERVISION SYSTEMS

As in other industrial sectors, as well as in the food sector, to guarantee maximum production efficiency it is necessary to have complete control of the process, in all its phases.

Dehumidification

Dehumidification

CLEAN, DRY AIR FOR FOOD PRODUCTION

In the food industry, constant monitoring of the relative humidity level of the air is essential to ensure the highest quality of the finished product. Dehumidifying the ambient air with the highest degree of hygiene is crucial for the transport and storage of ingredients such as flour, cocoa, milk and flavourings. With particular reference to hygroscopic substances, it is essential that the product humidity is as desired for production under all environmental conditions.

Transport

Transport

DENSE AND DILUTE PHASE TRANSPORT WITH PRE-MIXING OPTIONS

PiovanGroup industrial conveying systems are developed according to engineering design standards for a hygienic and safe process. These solutions are specifically designed and manufactured for the handling of food powders and viscous liquids, including flour, sugar, cocoa, honey, starch and inclusions. Specifically, the Group's conveying systems also allow ingredients to be pre-mixed during their handling.

Mixing

Sugar handling

Sugar handling

SPECIFIC SOLUTIONS FOR SUGAR TRANSPORT AND STORAGE

The PiovanGroup provides specific solutions for the management and treatment of hygroscopic products such as sugar.

More in detail, it designs and manufactures machinery for ambient air drying, conveying, shredding, storage and dosing.

More in detail, it designs and manufactures machinery for ambient air drying, conveying, shredding, storage and dosing.