Inspecta

- Sabit proses kontrolü

- Yüksek düzeyde doğruluk

- Kullanım kolaylığı

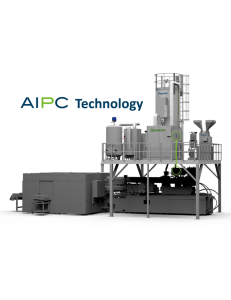

Inspecta detects the presence of acetaldehyde (Ac version), benzene (Be version) or Limonene (Lm version) in PET finished or semi-finished products. The former may be present in every final product because it is generated by the PET production process,the latter two as consequence of use of post consumer PET.

Inspecta is extremely ease to use and the measuring procedure is fully automatic and it takes less than 60 minutes, without requiring special skills.

The increase of sampling frequency and rapid results allow real control of the process.

Inspecta, numune toplayıp laboratuvara getirmeye gerek kalmadan üretim alanına kurulabilir.

Inspecta, analizi üretim zamanlamasıyla uyumlu hale getirerek hızlı düzeltici eylemlere izin verir. Tamamen otomatik analiz süreci, belirli becerilere, uzun hazırlık prosedürlerine veya kalibrasyon eğrilerinin oluşturulmasına sahip personel gerektirmez. Bu şekilde farklı fabrikalarda kurulan Inspecta'da sonuçlar güvenilir, yinelenebilir ve tekrarlanabilir olup analiz maliyetleri en aza indirilmiştir.