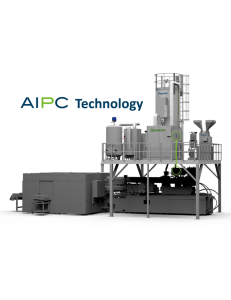

GenesysNext

De 400 à 5 000 m3/h

- Réduction des coûts du produit final

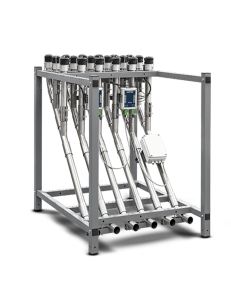

- Idéal pour produire avec du plastique recyclé

- Stabilité absolue du procédé

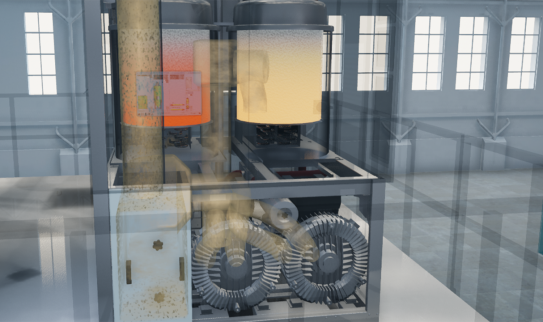

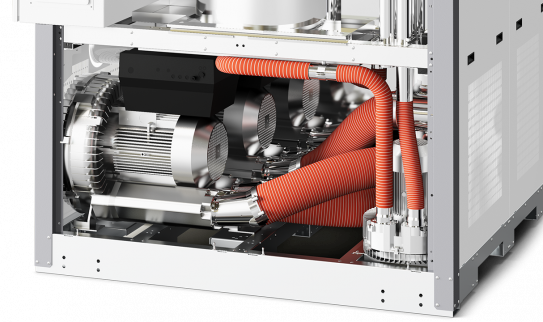

Haute performance, entièrement automatique, système de séchage à trémie unique permettant de réduire les frais de production.

Genesys Next est la solution de pointe pour

• Optimiser la consommation d'énergie

• Réduction des déchets grâce au traçage continu de la pression d'injection

Les données du détecteur d'humidité, l'humidité résiduelle en ligne dans les granulés de plastique, sont intégrées dans le contrôle GenesysNext.

GenesysNext fait également un pas en direction de l'économie circulaire: avec le système de filtration PureTech, disponible en option, qui permet une filtration avancée des COV présents dans l'air de traitement. Ceci est particulièrement nécessaire dans le cas des matériaux recyclés qui peuvent libérer des substances à bas point de fusion pendant le processus de chauffage ou d'injection et permet de préserver les tours de dessiccation.

Le contrôle de GenesysNext a été conçu pour combiner deux machines, avec un seul IHM, afin d'élargir la gamme d'application.