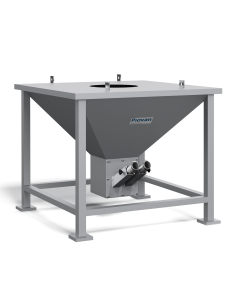

MBS Series

- Modular design adaptable to different production needs

- Customizable with a traditional discharge system or a suction probe

- Loading height designed to facilitate bag emptying without risks for the operator

The Piovan MBS Masterbatch Storage Station is a practical and efficient solution for the management of small quantities of masterbatch or additives, positioned directly next to the production lines. Designed to optimise operational efficiency, it guarantees a fast and safe supply of materials, reducing the risk of contamination and dispersion.

Available in two configurations - with 3 or 5 hoppers of 40 dm³ each - the station is mounted on a trolley with sturdy castors for easy movement around the plant. The ergonomic design, with a maximum loading height of 1120 mm, allows the operator to empty the bags easily and safely. A hinged lid with handle provides convenient closure, while the separation of the hoppers prevents material contamination. The front window allows immediate material level control, and a minimum sensor can be fitted to the rear for special applications.

Operational efficiency is guaranteed by the manual stainless steel slide gate, which ensures accurate and fast metering. The material can be discharged in the traditional way or through a suction probe for automatic transport, which can be combined with a single-phase receiver. The 40 mm diameter suction probes are easy to clean and require minimal maintenance, helping to reduce downtime and optimise the production process.

Thanks to these features, the Piovan MBS station is a versatile, safe and efficient solution for storing and managing materials in industrial processes.