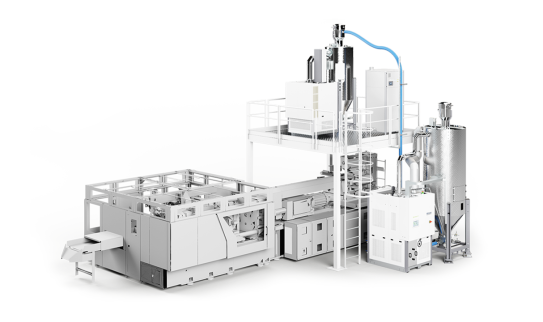

SoftBoost

- Compact design and plant versatility

- Reduction of heat loss and thermal stress of the resin

- Maximising production and reducing waste

SoftBoost is the innovative hopper designed for the rapid drying of regenerated PET with the aim of

• preserving the characteristics of the resin as much as possible

• obtain a high-quality finished product

• guaranteeing high productivity

The new, patented air channeling system allows the granule to be heated to the core in just 45 minutes to quickly bring it from 120 to 180 °C.

Completing the dehumidification directly or close to the injection molding machine allows the main dehumidification hoppers to be used at temperatures between 120 and 140 °C, thus limiting heat loss. At the same time, this makes it possible to work along the plasticising screw of the press at lower temperatures, reducing further thermal stress during moulding and limiting the production of scrap.

The reduced residence time of the material in the SoftBoost hopper, at the required working temperature, avoids unnecessary stress on the rPET and allows its mechanical, chemical and optical characteristics to be preserved.

The small size and versatility of the system allow fast material changes even during mold changes, greatly reducing downtime and maximising plant utilization.