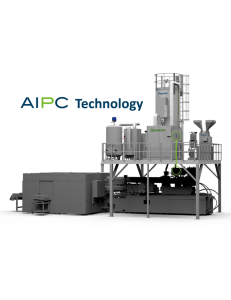

GN³

Up to 3,500 m³/h

- Material changeover in less than 2.5 hours thanks to the three-stage system

- Resin dehumidification in 5 hours thanks to high-exchange hoppers

- Energy savings thanks to high efficiency blowers

Built on the advanced GenesysNext platform, the GN³ accelerates dehumidification cycles by up to five hours, maximizing production throughput.

Designed to meet the market's demand for exceptional flexibility in material changeovers, the GN³ model maximizes profitable uptime with material changeovers achieved in under 2.5 hours, unlocking new levels of operational efficiency and productivity.

Self-adaptive technology guarantees the dehumidification process, ensuring constant and controlled dehumidification; furthermore, the dehumidification system has been enhanced with high efficiency blowers.

The three-hopper configuration dries resin through a progressive temperature profile, ensuring resin integrity and exceptional material quality throughout the process, particularly when processing rPET or rPET/PET blends.

Each hopper features an optimized cone size and a precise height-to-diameter ratio to enhance heat transfer to the granules, further boosting drying efficiency and reducing overall residence time.

The GN³ stands out for its compact design, which makes it easy to install on mezzanines.