TeslaTube

- Up to 90% energy savings compared to traditional waterbased heating

- Temperature maintained with a tolerance of ±0.1°C across the entire line

- Applicable at any point in the plant with rapid installation

TeslaTube is an advanced electromagnetic induction heating system specifically designed for food fluids such as chocolate, spreads, jellies, and honey, or in general, products that require controlled temperatures. Using cutting-edge technology, it ensures a precise temperature along the entire processing path, preventing solidification and preserving the quality of the product.

The operating principle is that of electromagnetic induction: a high-frequency alternating current passes through a conductor wound around the stainless steel piping, generating a magnetic field that induces currents in the piping itself, heating it evenly and transferring heat to the fluid in a controlled manner.

The modular architecture allows for simple installation and adaptability to any existing configuration. The system handles the entire processing line, from tanks to valves, from pumps to heat exchangers, ensuring precise thermal control. Quick-connect fittings simplify installation and maintenance, while standardization optimizes spare parts management.

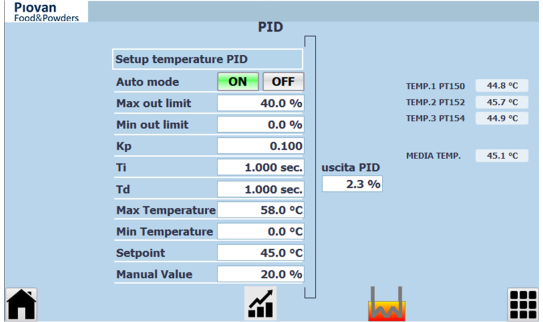

The advanced PLC controller, through distributed sensors, constantly monitors and adjusts the delivered power, maintaining the temperature of the fluid within ±0.1°C with extremely fast response times. The intuitive interface allows for real-time programming and monitoring.

Compared to traditional systems, TeslaTube offers significant advantages: superior energy efficiency with savings of up to 90%, elimination of energy-intensive components, uniform heat distribution, reduced startup times, and no risk of contamination.

The system can draw energy directly from photovoltaic inverters, eliminating intermediate energy conversions, increasing process efficiency, and significantly reducing the carbon footprint of

the entire production process.